Industry information

Company News

- Fluorocarbon aluminum veneer: a fashionable choice in modern architecture?

- Ceiling aluminum veneer: dual guarantee of quality and aesthetics

- Aluminum veneer: the "silver elf" in modern architecture

- Aluminum veneer for exterior walls: a fashionable outerwear for modern architecture

- Aluminum veneer customization, creating an artistic journey of personalized space

Industry dynamics

- Production process and technical analysis of aluminum veneer

- Surface coating process of aluminum veneer

- Ceiling aluminum veneer, the fashionable choice for modern home decor!

- Prediction of Price Trends in Aluminum Veneer Customization Market

- Application areas of 2.5mm carved aluminum veneer

Frequently asked questions

- How to choose the most suitable aluminum veneer material?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production and processing process of fluorocarbon aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 10, 2025 18:45:35

- Click:0

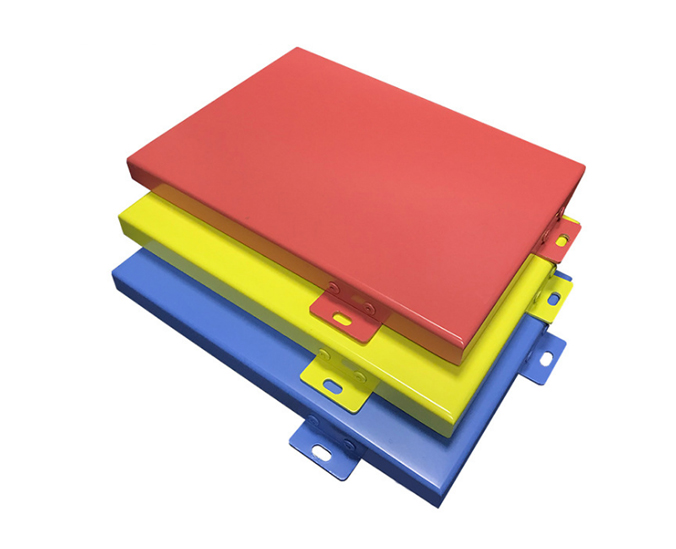

FluorocarbonAluminum veneerIt is a new type of building material with characteristics such as lightweight, high strength, corrosion resistance, and aesthetics, widely used in the field of architectural decoration. Let's take a look at the production and processing process of fluorocarbon aluminum veneer together.

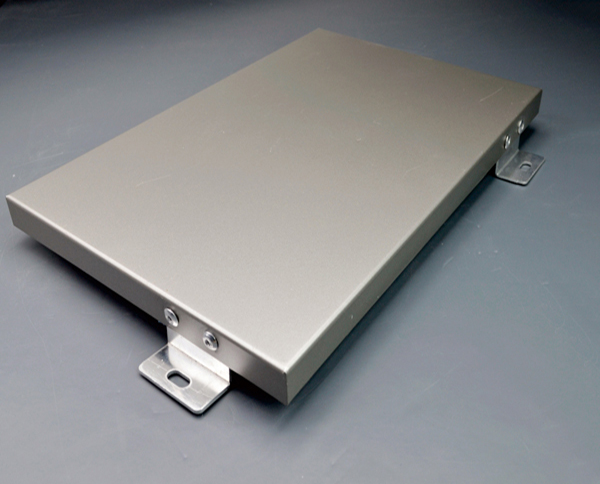

The production process of fluorocarbon aluminum veneer mainly includes raw material preparation, rolling, surface treatment, and coating. In the raw material preparation stage, it is necessary to select high-quality aluminum alloy materials as raw materials and carry out cutting, punching and other processing according to design requirements. In the rolling stage, it is necessary to accurately process the raw materials using tools such as CNC machines to obtain the required dimensions and shapes. In the surface treatment stage, it is necessary to polish and polish the rolled aluminum veneer to improve its surface quality. In the coating stage, fluorocarbon coating needs to be applied to the surface of aluminum veneer to enhance its corrosion resistance and aesthetics.

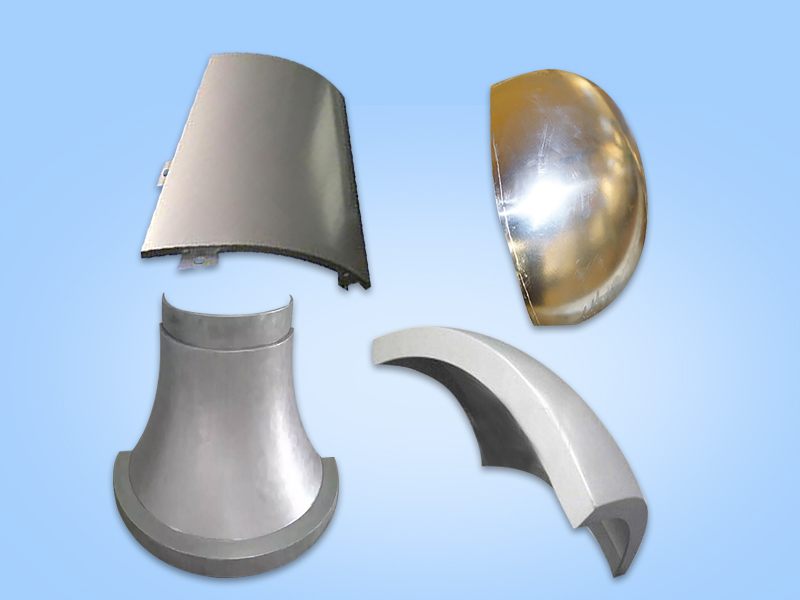

The processing of fluorocarbon aluminum veneer mainly includes cutting, bending, punching and other processes. In the cutting process, it is necessary to use tools such as CNC machines to accurately cut the aluminum veneer to obtain the desired size and shape. In the bending process, it is necessary to use bending machines and other tools to bend the aluminum veneer to meet different design requirements. In the punching process, it is necessary to use punching machines and other tools to punch the aluminum veneer to meet different installation requirements.

During the processing of fluorocarbon aluminum veneer, the following points should also be noted:

1. High machining accuracy: Due to the lightweight and high-strength characteristics of fluorocarbon aluminum veneer, it is necessary to ensure high machining accuracy during the machining process to avoid problems such as deformation or damage.

2. Good coating quality: Fluorocarbon coating is an important component of fluorocarbon aluminum veneer, so attention should be paid to the quality of the coating during the processing to ensure that fluorocarbon aluminum veneer has good corrosion resistance and aesthetics.

3. Safety measures should be taken: Fluorocarbon aluminum veneer will produce pollutants such as noise and dust during the processing, so corresponding safety measures need to be taken to ensure the health and safety of workers.

The production and processing process of fluorocarbon aluminum veneer is a complex and rigorous process that requires multiple processing steps to obtain high-quality products. With the continuous advancement of technology and the development of society, people have higher expectations and requirements for future architectural decoration. I believe that fluorocarbon aluminum veneer will play a more important role in future architectural decoration!

Customer service QQ

Customer service QQ