Industry information

Company News

- Fluorocarbon aluminum veneer: the "hidden aristocrat" in modern architecture

- Aluminum veneer exterior wall, bringing a new level of architectural "beauty"

- The secret behind aluminum veneer: the new favorite of light luxury lifestyle

- Ceiling aluminum veneer: the secret weapon for creating fashionable spaces

- Aluminum veneer ceiling: a work of art that combines fashion and practicality

Industry dynamics

- Environmental advantages and promotion prospects of aluminum veneer

- The environmental protection concept of customized aluminum veneer practices green building to create a sustainable future

- Ceiling aluminum veneer, the unique style of modern architecture

- Aluminum veneer for exterior walls: a perfect combination of architectural aesthetics and practicality

- Aluminum veneer: a modern interpretation of architectural aesthetics

Frequently asked questions

- How to improve the wind resistance performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and technical analysis of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-13 07:4:58

- Click:0

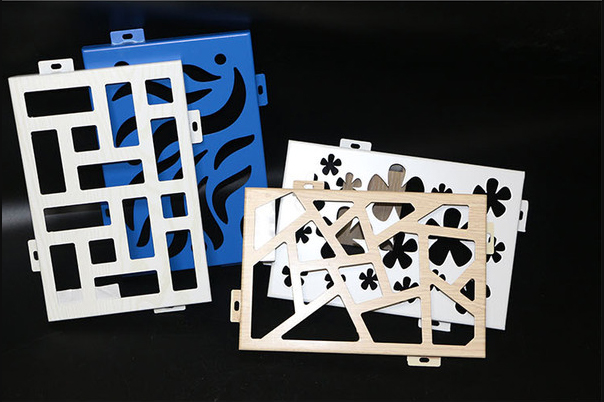

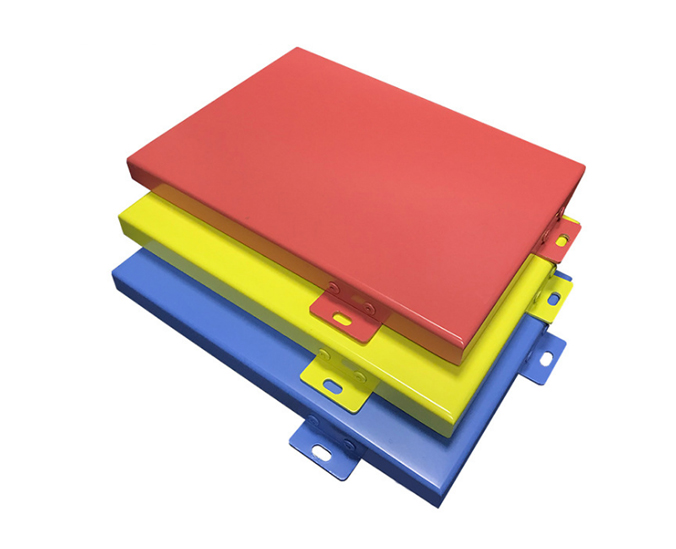

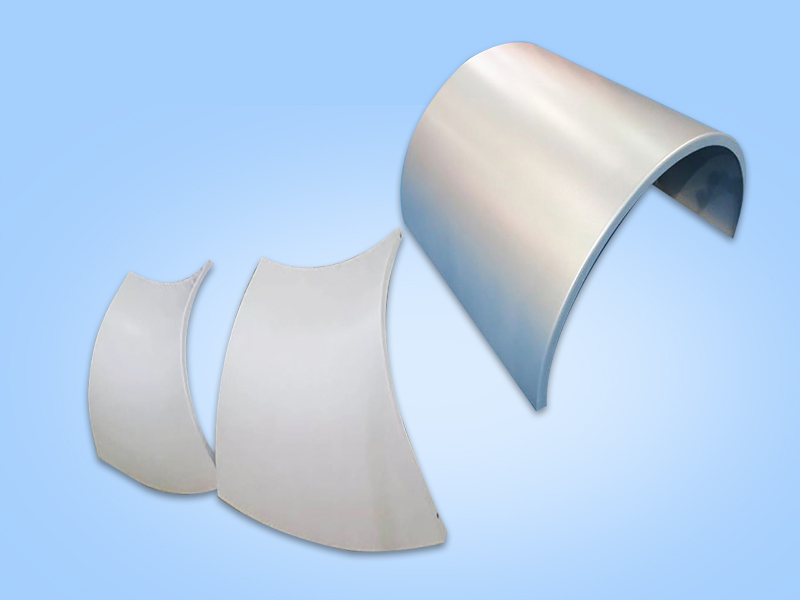

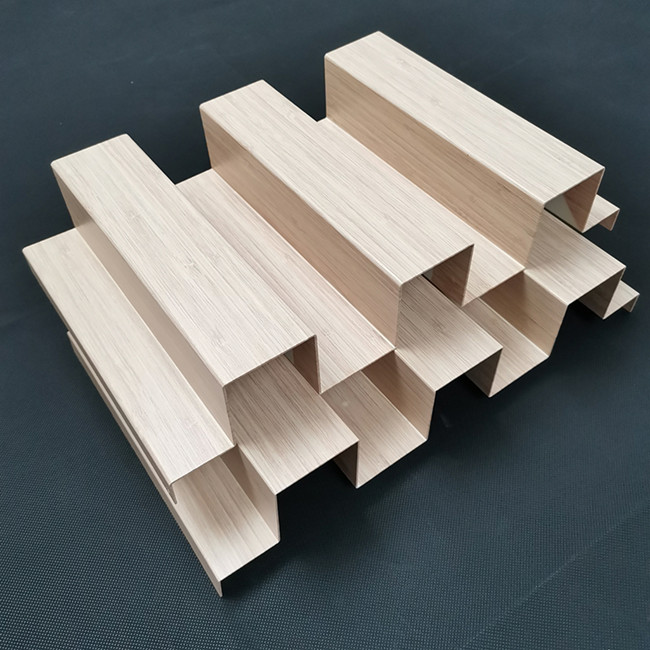

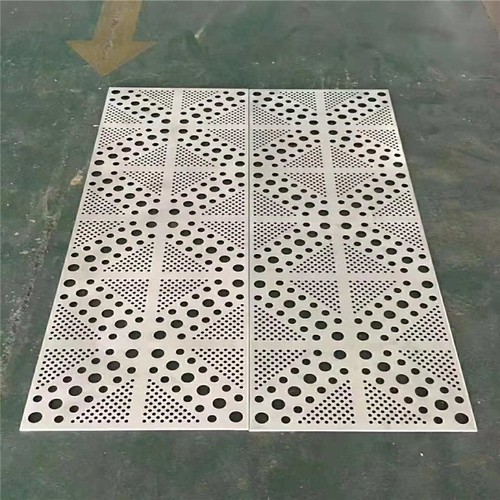

Aluminum veneerIt is a lightweight, high-strength, and corrosion-resistant building material widely used in fields such as building curtain walls, interior decoration, and transportation facilities. The production process mainly includes raw material procurement, cutting, rolling, surface treatment, and packaging. The following will provide a detailed introduction to the production process and technical analysis of aluminum veneer.

1. Raw material procurement

The main raw materials for aluminum veneer are aluminum and surface treatment agents. Aluminum materials are generally selected from 1100 series or 3003 series aluminum alloy materials, which have good strength and corrosion resistance. Surface treatment agents are selected based on their different applications, such as polyester coatings, fluorocarbon coatings, etc.

1. Cutting materials

The cutting and processing of aluminum veneer is the process of cutting and processing aluminum materials according to design requirements. Generally speaking, the cutting of aluminum veneer requires the use of professional CNC cutting machines to ensure dimensional accuracy and surface quality.

1. Rolling

The rolling of aluminum veneer is the process of processing aluminum into the desired shape. Generally speaking, the rolling of aluminum veneer requires the use of large high-speed rolling mills to ensure the accuracy of thickness and width. During the rolling process, aluminum materials also need to be stretched and straightened to ensure their strength and flatness.

1. Surface treatment

The surface treatment of aluminum veneer is the process of coating or spraying it. Generally speaking, the surface treatment of aluminum veneer requires the use of high-temperature baking equipment for heating treatment, forming a layer of oxide film on its surface to improve its corrosion resistance and wear resistance. It is also necessary to polish and clean the surface to ensure the quality and adhesion of the coating.

1. Packaging

The packaging of aluminum veneer is the process of packaging and transporting it. Generally speaking, the packaging of aluminum veneer requires the use of moisture-proof, shockproof, fireproof and other materials to ensure its safety and integrity during transportation.

The production process of aluminum veneer includes raw material procurement, cutting, rolling, surface treatment, and packaging. In the production process, it is necessary to pay attention to controlling the quality of each link to ensure that the quality and performance of the final product meet the requirements. We also need to continuously introduce new technologies and materials, improve production efficiency and product quality to meet market demand.

- previous page:Production cost and price trend of aluminum veneer

- Next page:What is the production process of aluminum veneer?

Customer service QQ

Customer service QQ