Frequently asked questions

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer ceiling: the beauty of modern simplicity

- Ceiling aluminum veneer: a secret weapon for creating new heights in home decor

- Aluminum veneer: a fashionable outerwear for industrial buildings

- Ceiling aluminum veneer: a perfect combination of fashion and practicality

Industry dynamics

- Aluminum veneer ceiling: the new darling of creating fashionable spaces

- Aluminum veneer: the fashionable choice for modern architecture

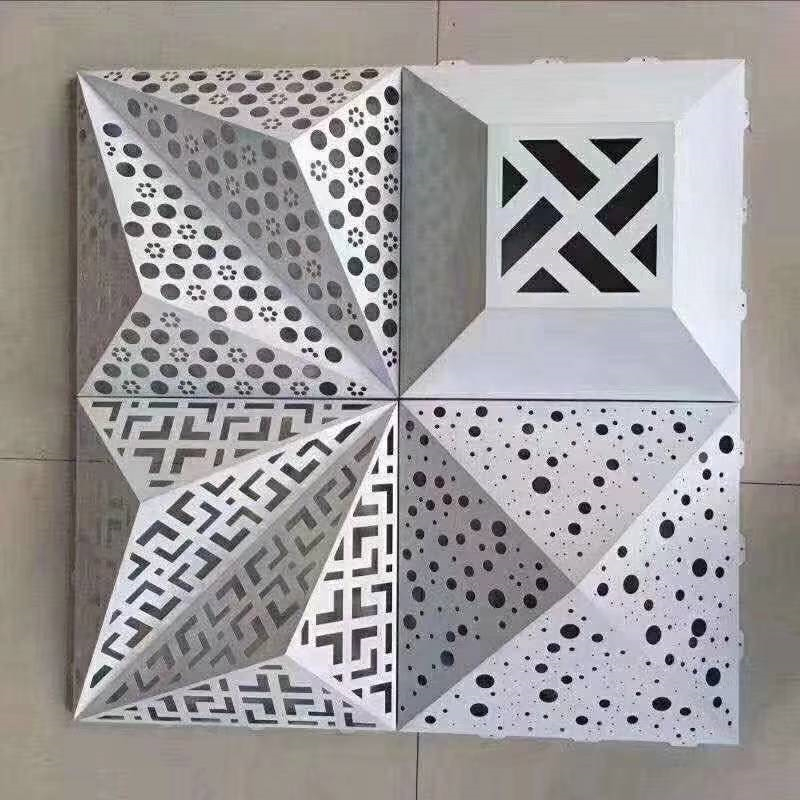

- Characteristics and advantages analysis of hollow aluminum veneer in walls

- Reflection characteristics and light utilization of aluminum veneer

- Selection and use of high-quality perforated aluminum veneer for curtain wall materials

Frequently asked questions

- How to choose the most suitable aluminum veneer material?

- How to improve the corrosion resistance of aluminum veneer?

- What is aluminum veneer?

- How to choose high-quality aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the wind resistance performance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 4, 2025 21:39:25

- Click:0

How to improveAluminum veneerWhat is the wind resistance performance?

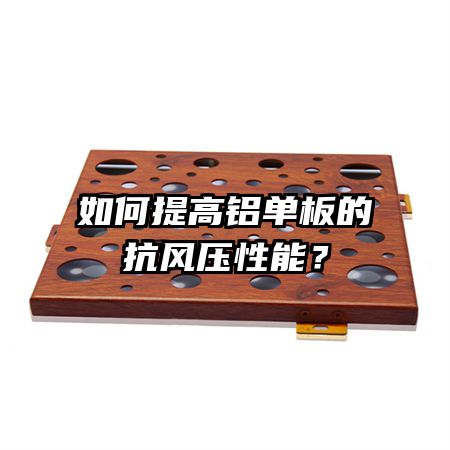

With the continuous development of the construction industry, aluminum veneer, as a new type of building material, has been widely used in exterior wall decoration of buildings. However, due to the frequent attacks of strong winds on the exterior walls of buildings, the wind resistance performance of aluminum veneer has become an important technical indicator. This article will explore how to improve the wind pressure resistance performance of aluminum veneer from the following four aspects.

1、 In terms of material selection

1. High quality aluminum material: Choose aluminum material with high strength and corrosion resistance to ensure the wind pressure resistance of aluminum veneer. At present, there are many aluminum plates of different qualities on the market, and it is necessary to choose high-quality aluminum plates to ensure the best wind pressure resistance performance.

2. Aluminum plate thickness: While meeting the requirements of aesthetic appearance, the thickness of aluminum plate is also one of the key factors affecting its wind pressure resistance performance. Therefore, it is necessary to choose the appropriate thickness according to the actual usage environment to ensure the wind pressure resistance performance of aluminum veneer.

3. Coating material: Coating materials can not only beautify the appearance, but more importantly, increase the wind pressure resistance of aluminum veneer. It is recommended to use high-quality PVDF coating to ensure excellent durability and stability of aluminum veneer.

2、 In terms of structural design

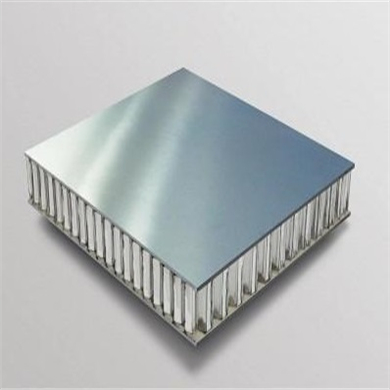

1. Panel connection method: The connection method of aluminum veneer has a significant impact on its wind pressure resistance performance. The use of high-strength and rigid mechanical locking edges or adhesive connections can improve the overall strength and stability of aluminum veneer, thereby enhancing its wind pressure resistance performance.

2. Bracket structure: Bracket is the main structure for fixing aluminum veneer, and it is also an important factor affecting its wind pressure resistance performance. By using high-quality aluminum materials and strengthening the horizontal and vertical strength of the bracket, the wind pressure resistance performance of the aluminum veneer can be effectively improved.

3. Board shape: In order to avoid excessive deformation of the board surface when the exterior wall is exposed to wind, appropriate wind resistant structures need to be designed on the board surface. Structures such as wavy, U-shaped, and Z-shaped can enhance the wind pressure resistance test results of aluminum veneer.

3、 Installation and construction aspects

1. Construction quality: The installation quality of aluminum veneer directly affects its wind resistance performance. Therefore, construction personnel are required to have rich construction experience, proficient skills, strictly follow the design plan for construction, and do a good job in every detail.

2. Adhesive selection: The quality and selection of adhesive directly affect the bonding strength of aluminum veneer. It is recommended to use high-quality adhesive products from reputable brands to ensure the bonding strength between aluminum veneer and brackets.

3. Installation process: During the installation of aluminum veneer, it is necessary to carry out pre-treatment, measurement, cutting and other work, strictly control each link, and do a good job in assembly welding, adhesive fixation and other processes to ensure the process flow and construction quality.

4、 Wind pressure test aspect

1. Wind pressure test standards: Before improving the wind resistance performance of aluminum veneer, it is necessary to first understand the relevant national and regional standards and specifications, such as ASTM, EN, GB, etc., to ensure that the aluminum veneer meets the standard requirements.

2. Experimental data analysis: During the wind pressure test, it is necessary to conduct a comprehensive, systematic, and accurate analysis of the test data to understand the wind pressure resistance performance of aluminum veneer. At the same time, based on the actual usage environment and standard requirements, continuously optimize the design and process of aluminum veneer to improve its wind pressure resistance performance.

3. Test report evaluation: The wind pressure resistance test report of aluminum veneer is an important basis for evaluating its wind pressure resistance performance. It is necessary to select an authoritative third-party organization for testing and evaluation, and conduct detailed analysis and comparison of the test report to provide reference for the subsequent production and application of aluminum veneer.

5、 Summary:

In summary, improving the wind resistance performance of aluminum veneer requires multiple aspects, including material selection, structural design, installation and construction, and wind pressure testing. Only by comprehensively, systematically, and scientifically mastering these key technologies can we produce aluminum veneers with excellent wind pressure resistance and ensure their safety and stability in application.

Customer service QQ

Customer service QQ