Frequently asked questions

Company News

- Ceiling aluminum veneer: the new darling of modern architectural aesthetics?

- Aluminum veneer: not just decoration, but also a bridge of art!

- Aluminum veneer: the "fashionable coat" of modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer: the 'invisible hero' of modern architecture

Industry dynamics

- New trend ceiling aluminum veneer, creating the new favorite of fashionable spaces!

- Aluminum veneer customization, creating exclusive space aesthetics

- Aluminum veneer for exterior walls: the beauty of architecture, details determine everything

- Aluminum veneer: the new darling of the construction industry, the perfect combination of fashion and practicality

- Unique design! Wood grain carved aluminum veneer creates a unique architectural style

Frequently asked questions

- How to extend the service life of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to improve the environmental performance of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to store and transport aluminum veneer correctly?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-05 12:00:31

- Click:0

How to store and transport correctlyAluminum veneer?

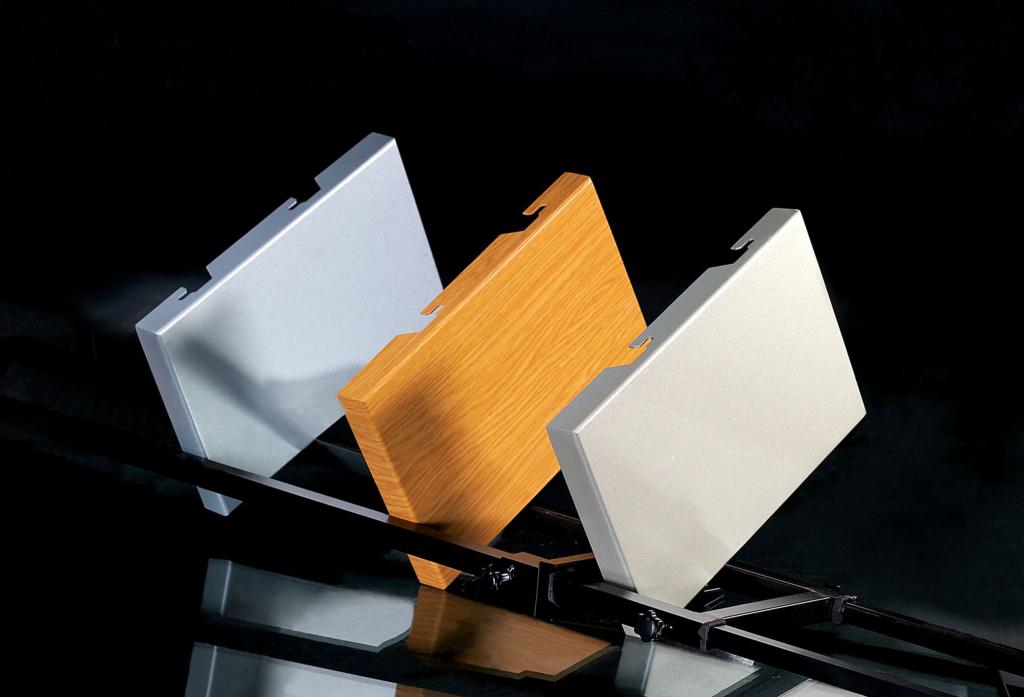

Aluminum veneer is a common building decoration material widely used in indoor and outdoor spaces. Proper storage and transportation are crucial to ensure the quality and effectiveness of aluminum veneer. This article will elaborate on how to properly store and transport aluminum veneers from the following four aspects.

1、 Storage environment

1. Storage temperature: Aluminum veneer should be stored in a dry and ventilated environment, avoiding exposure to sunlight and high temperatures. The indoor storage temperature should be controlled between 15-30 degrees Celsius to avoid too low or too high a temperature affecting the performance of the aluminum plate.

2. Storage humidity: Aluminum veneer is sensitive to humidity, so it should be stored in an environment with stable relative humidity. Excessive humidity can cause rusting of aluminum plates, while low humidity can easily lead to deformation of aluminum plates. The suitable relative humidity range is 40% -70%.

3. Storage location: When storing aluminum veneer, avoid prolonged contact with the ground. It is best to use specialized shelves or brackets for storage to prevent moisture and scratches.

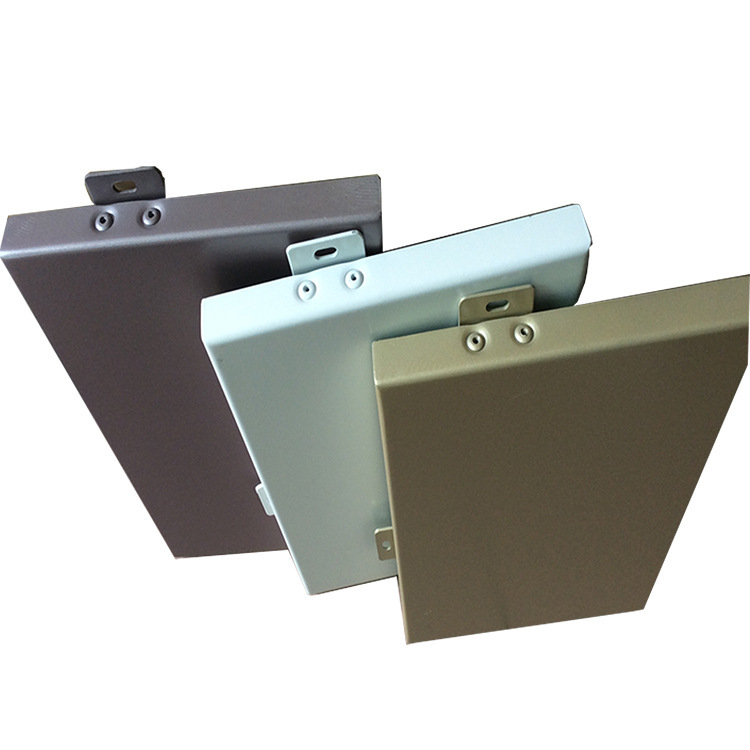

2、 Packaging method

1. Protective layer: During storage and transportation, the surface of aluminum veneer is prone to scratching and wear. Therefore, when packaging aluminum veneer, a protective layer should be applied to the surface to prevent scratches and damage.

2. Packaging materials: select appropriate packaging materials, such as foam board, cardboard or wooden frame, which can provide adequate protection and avoid corrosion of the packaging materials to the aluminum plate.

3. Fixing method: Ensure that the aluminum veneer is firmly fixed in the packaging to prevent sliding and collision during transportation, which may cause unnecessary damage.

3、 Transportation mode

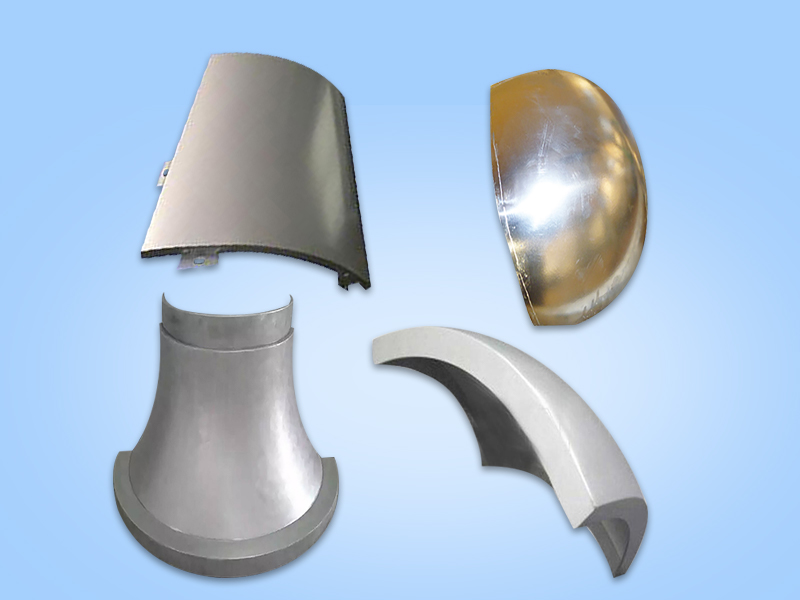

1. Transportation tool selection: Choose transportation tools that are suitable for the size and weight of aluminum veneer, such as trucks, containers, etc. Ensure that the transportation vehicles are flat and clean to avoid squeezing and contaminating the aluminum plates.

2. Temperature control during transportation: When transporting aluminum veneer in winter or cold regions, it is important to avoid the impact of low temperatures on the aluminum sheet. Heating or insulation measures can be chosen.

3. Transportation process monitoring: For long-distance transportation, it is necessary to strengthen the monitoring and management of the transportation process to ensure the safety and integrity of aluminum veneer. Timely address potential issues that may arise during transportation, such as road bumps, vibrations, etc.

4、 Operation precautions

1. Handling method: When handling aluminum veneer, excessive squeezing and impact should be avoided, and it should be handled gently to avoid deformation and damage.

2. Protective measures: When handling and installing aluminum veneer, appropriate personal protective equipment such as gloves, safety shoes, etc. should be used to ensure the safety of operators.

3. Cleaning and maintenance: During storage and transportation, regularly clean the surface of aluminum veneer to prevent dust and pollutant accumulation, and maintain the bright appearance of the aluminum sheet.

Summary:

Proper storage and transportation are key to ensuring the quality and effectiveness of aluminum veneer. By properly setting up the storage environment, packaging and transportation, and paying attention to operational details, we can ensure that aluminum veneers are not damaged during storage and transportation, thereby better meeting the needs of building decoration.

- previous page:How to extend the service life of aluminum veneer?

- Next page:What is aluminum veneer?

Customer service QQ

Customer service QQ