Frequently asked questions

Company News

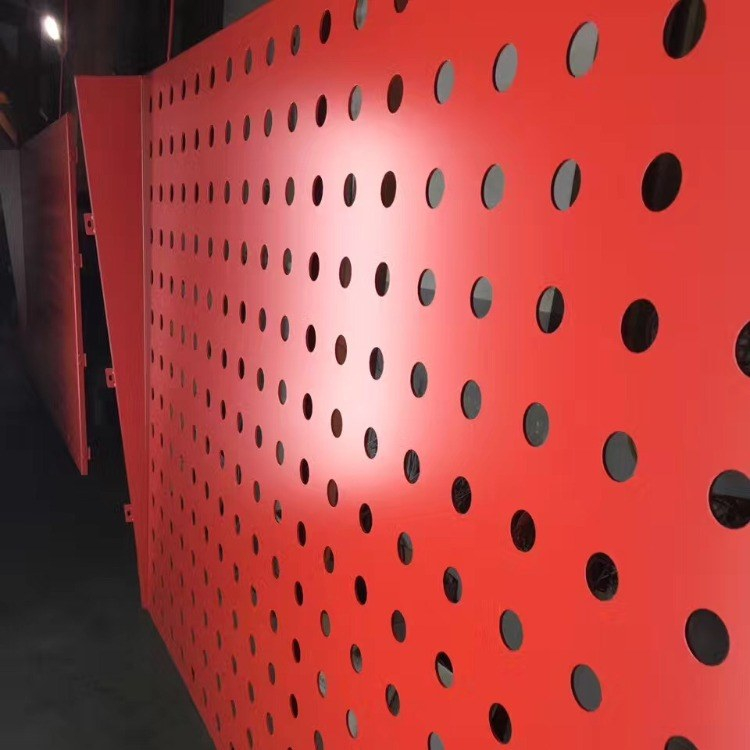

- Aluminum veneer for exterior walls: a fashionable outerwear for modern architecture

- Ceiling aluminum veneer: a perfect fusion of fashion and practicality

- Ceiling aluminum veneer: a perfect combination of fashion and practicality

- The performance of aluminum veneer in thermal insulation, sound insulation and noise reduction, and its application in cold regions

- Aluminum veneer customization: infinite possibilities for personalized space

Industry dynamics

- Detailed installation steps for 3mm ceiling aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

- Personalized customization, aluminum veneer new fashion

- Aluminum veneer ceiling, the secret weapon for enhancing home aesthetics

- UV protection performance of imitation wood grain aluminum veneer

Frequently asked questions

- How to choose to purchase high-quality aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to choose the most suitable aluminum veneer material?

- How to improve the corrosion resistance of aluminum veneer?

- How to choose high-quality aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the corrosion resistance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-05 09:07:13

- Click:0

1、 Material selection

1. Appropriate alloy composition: When selecting aluminum veneer materials, it is advisable to choose the appropriate alloy composition as much as possible. According to different usage environments, aluminum alloys containing different proportions of magnesium, manganese, silicon, and other elements can be selected. For example, aluminum veneers used in marine or industrial environments should choose aluminum alloys containing higher levels of magnesium and manganese.

2. Production process: During the production of aluminum veneer, it is necessary to ensure the purity of raw materials and processing accuracy to ensure that the quality of aluminum veneer meets the standards. In addition, it is necessary to avoid introducing impurities and air pollutants during the production process, which can affect the corrosion resistance of materials.

3. Testing and evaluation: Aluminum veneer should be regularly tested and evaluated to ensure its normal use. Timely take corresponding repair measures for material defects and existing problems.

2、 Surface treatment

1. Anodizing: For aluminum veneer, anodizing is an effective surface treatment method. Anodizing can form a protective layer of aluminum oxide with a thickness not exceeding 25 microns, improving the hardness and corrosion resistance of aluminum veneer.

2. Electrophoretic coating: Electrophoretic coating is a new type of coating technology. Uniformly adhere the coating to the surface of aluminum veneer through electrophoretic deposition, and undergo drying and curing treatment. This processing method has the characteristics of good sealing, wear resistance, and corrosion resistance.

3. Mechanical scratches: During surface treatment, avoid using mechanical tools such as scrapers to scratch the surface. Because these scratches greatly reduce the corrosion resistance of aluminum veneer.

3、 Coating selection

1. Multi layer coating: When selecting coatings, priority should be given to multi-layer coating. Multi layer coating can not only increase the thickness of the coating, but also add some special substances such as zinc powder to the coating to improve its corrosion resistance. Meanwhile, multi-layer coating can also provide better insulation and thermal insulation effects for aluminum veneer.

2. Color selection: When choosing coating colors, light colors should be given priority because light colored coatings have the ability to reflect light, which can prevent temperature rise caused by light exposure and reduce the possibility of coating aging and corrosion.

3. UV coating: When selecting coatings, give priority to using UV coating. UV coating not only improves the hardness and wear resistance of the coating, but also forms a special film layer on the surface of the coating, enhancing its corrosion resistance.

4、 Maintenance and upkeep

1. Regular testing and cleaning: Aluminum veneer should avoid using chemicals or irritating cleaning agents as much as possible during normal use and daily cleaning processes, as these can have a negative impact on coating damage and corrosion. It is recommended to use warm water or detergent for cleaning, and promptly dry the surface after cleaning.

2. Regular maintenance and repair: In order to maintain the good condition of aluminum veneer, it should be regularly maintained and repaired. For example, for aged coatings, recoating or sanding treatment can be carried out to restore coating quality and protect aluminum veneer.

3. Avoid collisions and physical damage: In practical use, aluminum veneers should be protected from collisions and physical damage, as they can produce microscopic defects and reduce the corrosion resistance of aluminum veneers.

5、 Summary:

Improving the corrosion resistance of aluminum veneer is a comprehensive process. By selecting appropriate materials, strengthening surface treatment, choosing high-quality coatings, and conducting scientific and reasonable maintenance, the corrosion resistance of aluminum veneer can be effectively improved, protecting its long-term stable use. I hope the content described in this article can be enlightening and helpful to readers.

Customer service QQ

Customer service QQ