Industry information

Company News

- Aluminum veneer for exterior walls: an evolutionary theory of the "coat" of modern architecture

- Aluminum veneer for exterior walls, the new darling of architectural aesthetics

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry?

- Ceiling aluminum veneer: a fashionable choice in modern architecture

- The secret behind aluminum veneer: the new favorite of light luxury lifestyle

Industry dynamics

- Detailed description and implementation plan of aluminum veneer customization process flow

- Aluminum veneer customization, creating a new proposition for personalized space

- Can aluminum veneer be used for building eaves design?

- Selection and production process of environmentally friendly materials for carved aluminum veneer

- Fluorocarbon aluminum veneer: the "golden partner" of architectural aesthetics

Frequently asked questions

- How to improve the environmental performance of aluminum veneer?

- How to choose high-quality aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- What is aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-13 04:08:11

- Click:0

Aluminum veneerAs a common building material, its production process is an important guarantee for ensuring product quality and safety. This article will provide a detailed introduction to the production process of aluminum veneer.

1、 Raw material procurement

The production of aluminum veneer first requires the procurement of high-quality aluminum alloy materials. These materials typically include different types of aluminum alloy sheets such as 1100, 3003, 5052, as well as other auxiliary materials such as screws, nails, etc. The purchased raw materials need to undergo strict quality testing to ensure the quality and safety of the products.

2、 Cutting and processing

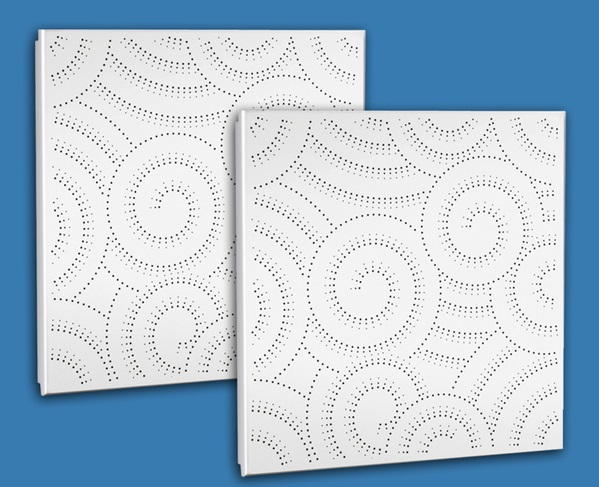

The purchased raw materials need to be cut and processed for subsequent processing and manufacturing. Cutting processing usually includes multiple steps such as shearing, punching, bending, etc. These steps require the use of professional mechanical equipment and tools to ensure the accuracy and quality of the product.

3、 Surface treatment

The surface treatment of aluminum veneer is an important step in ensuring product quality and aesthetics. Surface treatment usually includes multiple steps such as anodizing, fluorocarbon spraying, electrophoretic coating, etc. These steps can effectively improve the weather resistance and corrosion resistance of aluminum veneer, and can also print various patterns and texts to achieve advertising effects.

4、 Assembly and installation

The assembly and installation of aluminum veneer is the final step in the entire production process. During the assembly and installation process, customized design is required based on customer needs and personalized requirements to meet different architectural styles and personalized needs. Attention should be paid to safety issues during the assembly and installation process to ensure the safety and stability of the construction process.

The production process of aluminum veneer includes multiple stages such as raw material procurement, cutting and processing, surface treatment, and assembly and installation. These processes require strict adherence to relevant standards and regulations to ensure the quality and safety of the product. Environmental protection issues need to be taken into account during the production process to reduce the impact on the environment.

Customer service QQ

Customer service QQ