Industry information

Company News

- The Fashion Revolution of Ceiling Aluminum Veneer: Creating a New Favorite Personalized Space

- Aluminum veneer for exterior walls: a fashionable outerwear for modern architecture

- Aluminum veneer: the 'invisible hero' of modern architecture

- Aluminum veneer ceiling, a ceiling with home aesthetics

- Ceiling aluminum veneer: a new proposition for light luxury living

Industry dynamics

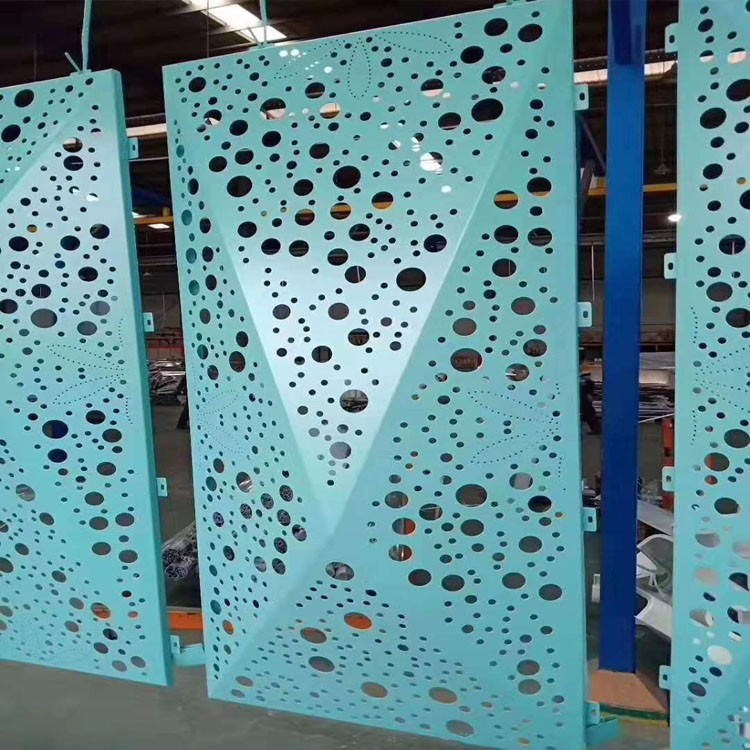

- Environmental performance analysis of carved aluminum veneer

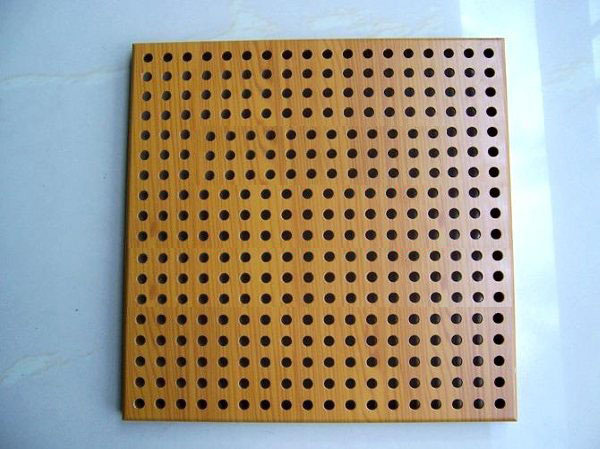

- Design and decorative effect of perforated carved aluminum veneer

- Fluorocarbon aluminum veneer: the fashion darling of the construction industry

- Ceiling aluminum veneer, creating a new trend of fashionable space

- Detailed explanation and implementation suggestions for customized aluminum veneer process flow

Frequently asked questions

- How to choose high-quality aluminum veneer?

- How to store and transport aluminum veneer correctly?

- What is aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Surface coating process of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-02 19:46:04

- Click:0

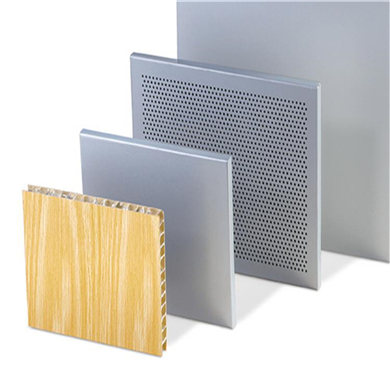

Aluminum veneerIt is a material widely used in the fields of building curtain walls, interior decoration, etc. Its surface coating process has a crucial impact on its aesthetics and service life. This article will provide a detailed introduction to the classification, characteristics, and application of surface coating processes for aluminum veneer.

1、 Classification of surface coating processes for aluminum veneer

The surface coating process of aluminum veneer can be mainly divided into the following types:

1. Anodizing treatment: A layer of oxide film is formed on the surface of aluminum veneer through electrolytic oxidation technology, which has the advantages of corrosion resistance, wear resistance, high temperature resistance, etc., and is commonly used in outdoor building decoration.

2. Fluorocarbon spraying: Spray a layer of fluorocarbon coating on the surface of aluminum veneer, which has the advantages of weather resistance, UV resistance, acid and alkali resistance, and is suitable for high-end building decoration.

3. Powder coating: Dip the aluminum veneer into powder coating and then bake it at high temperature to attach it to the aluminum veneer, which has good anti-corrosion and decorative properties and is suitable for indoor building decoration.

2、 Characteristics of surface coating process for aluminum veneer

Different surface coating processes have their own characteristics, as follows:

1. Anodizing treatment: It has high hardness and wear resistance, but there are few color options available, only black or white can be chosen.

2. Fluorocarbon spraying: Rich in color, good weather resistance, strong UV resistance, but relatively expensive.

3. Powder coating: Rich in color and strong decorative, but poor weather resistance and susceptible to acid and alkali corrosion.

3、 Application of surface coating technology for aluminum veneer

Different surface coating processes are suitable for different occasions, as follows:

1. Anodizing treatment: suitable for outdoor building decoration, such as large commercial squares, airport terminals, etc.

2. Fluorocarbon spraying: suitable for high-end building decoration, such as office buildings, hotels, etc.

3. Powder coating: suitable for indoor building decoration, such as residential buildings, offices, etc.

4、 Conclusion

The surface coating process of aluminum veneer is one of the important factors to ensure its beauty and service life. By selecting and applying different surface coating processes reasonably, the needs of different occasions can be met, and the added value and market competitiveness of aluminum veneer can also be improved.

Customer service QQ

Customer service QQ