Industry information

Company News

- Unveiling the Charm and Value of Exterior Aluminum Veneers

- Aluminum veneer for exterior walls, the new darling of modern architecture!

- New favorite of ceiling - aluminum veneer has infinite charm

- Ceiling aluminum veneer: dual guarantee of quality and aesthetics

- Ceiling aluminum veneer: the new darling of modern architectural aesthetics?

Industry dynamics

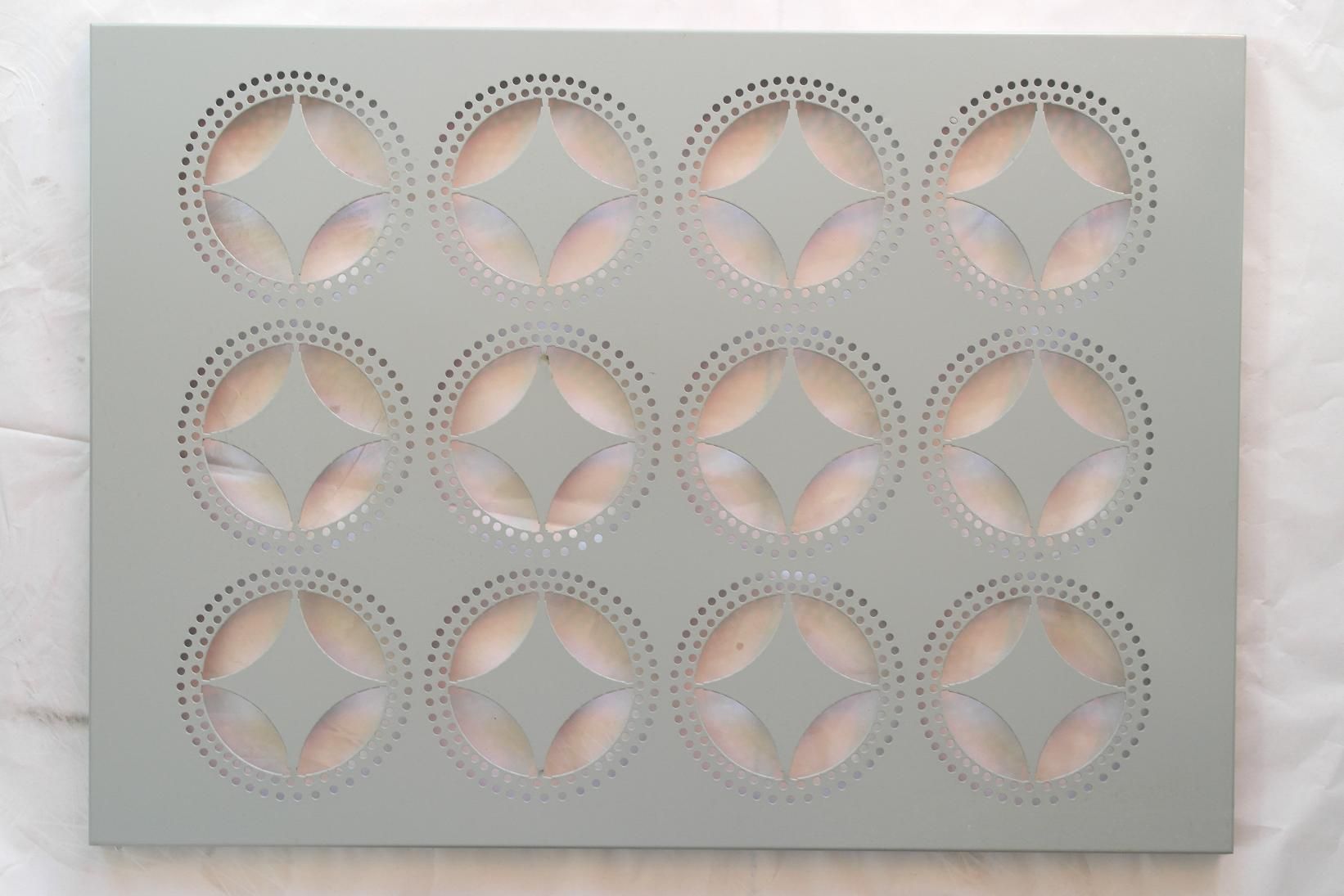

- Analysis of the advantages of environmentally friendly material special-shaped carved aluminum veneer

- Aluminum veneer: a fashionable choice in modern architecture

- Aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space!

- Ceiling aluminum veneer: an elegant choice for modern homes, your home can also be so fashionable!

Frequently asked questions

- How to choose the most suitable aluminum veneer material?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to choose high-quality aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the seismic performance of fluorocarbon aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 9, 2025 16:39:30

- Click:0

FluorocarbonAluminum veneerIt is a building material widely used in fields such as architecture, billboards, curtain walls, etc. Its seismic performance is one of the important concerns for consumers. The seismic performance of fluorocarbon aluminum veneer will be detailed below.

1. Concept of seismic performance

Seismic performance refers to the ability of fluorocarbon aluminum veneer to resist natural disasters such as earthquakes, including compressive, tensile, and bending resistance.

1. Influencing factors

The seismic performance of fluorocarbon aluminum veneer is influenced by various factors, mainly including the following aspects:

(1) The quality of materials: The strength and hardness of fluorocarbon aluminum veneer materials have a significant impact on seismic performance. High quality materials can produce fluorocarbon aluminum veneer products with better seismic performance.

(2) Structural design: The structural design of fluorocarbon aluminum veneer is also an important factor affecting its seismic performance. Reasonable structural design can improve the seismic resistance of fluorocarbon aluminum veneer.

(3) Installation method: The installation method of fluorocarbon aluminum veneer can also affect its seismic performance. For example, fluorocarbon aluminum veneer installed in a fixed manner has better seismic resistance compared to fluorocarbon aluminum veneer installed in a suspended manner.

It should be noted that the seismic performance of fluorocarbon aluminum veneer is not necessarily better the higher. In practical applications, selection and design need to be based on specific circumstances. For example, in the design of building exterior walls, it is necessary to consider whether the seismic performance of fluorocarbon aluminum veneer can withstand the influence of natural factors such as wind and rain to ensure the stability of the building; In the design of interior decoration, it is necessary to consider whether the seismic performance of fluorocarbon aluminum veneer can meet the weight of furniture, appliances, and other items to ensure its service life and stable performance.

The seismic performance of fluorocarbon aluminum veneer is an important indicator that has a significant impact on the appearance and performance of the entire product. Consumers should choose fluorocarbon aluminum veneer products that meet the standards and follow the manufacturer's instructions and maintenance recommendations to ensure the service life and stable performance of fluorocarbon aluminum veneer. Attention should also be paid to the characteristics of materials and structural limitations during design and installation to ensure that the construction effect meets the requirements.

Customer service QQ

Customer service QQ