Industry information

Company News

- Aluminum veneer exterior wall, building a fashionable protective shield for the home

- Aluminum veneer for exterior walls, the fashionable new favorite of urban architecture

- Ceiling aluminum veneer: the beauty of light luxury, the new darling of aluminum materials

- Fluorocarbon aluminum veneer: the beauty of architecture, the choice of details

- The important role of aluminum veneer in environmentally friendly decoration

Industry dynamics

- Aluminum veneer ceiling: an elegant choice for modern homes

- Aluminum veneer: the new favorite of "fashionable luxury" in the construction industry

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Customize Your Style - New Proposition for Aluminum Veneer

- Ceiling aluminum veneer, creating a new trend of modern home decor

Frequently asked questions

- How to choose high-quality aluminum veneer?

- What is aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to materials and processes of perforated ceiling aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-01 16:33:49

- Click:0

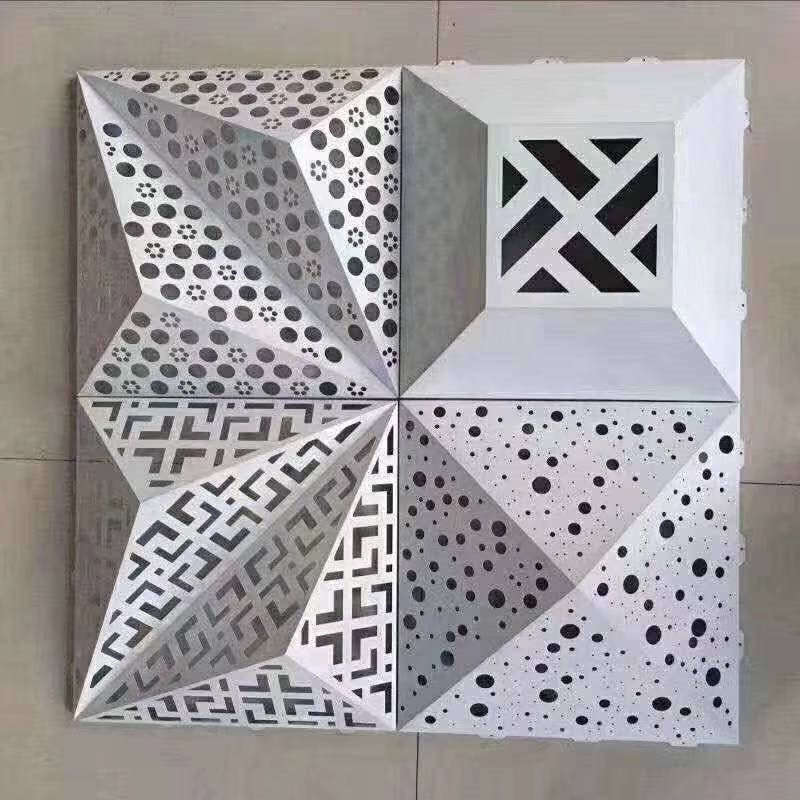

Punched ceilingAluminum veneerIt is a new type of building material with advantages such as lightweight and high strength, good sound insulation effect, and good breathability. The material and process of its production are also very important. Below, we will introduce in detail the material and process of perforated ceiling aluminum veneer.

1、 Materials

1. Aluminum alloy sheet

The main material of perforated ceiling aluminum veneer is high-strength aluminum alloy sheet, which has the characteristics of light weight, high strength, good corrosion resistance and oxidation resistance, and is very suitable for use in the building decoration industry.

2. Punching mold

The perforated ceiling aluminum veneer is processed by punching molds, so the quality and accuracy of the molds have a significant impact on the quality and aesthetics of the perforated ceiling aluminum veneer.

3. Surface treatment process

Punched ceiling aluminum veneer requires surface treatment processes to achieve better performance. Common surface treatment processes include anodizing, electrophoretic coating, etc. These processes can enhance the corrosion resistance and oxidation resistance of aluminum veneer, thereby improving its service life.

2、 Craftsmanship

1. Cutting and processing

Firstly, it is necessary to cut the aluminum alloy sheet into the required size and shape to prepare for subsequent punching processing.

2. Punching processing

By using punching molds to punch aluminum alloy sheets, various patterns and designs are formed, giving them a more three-dimensional and rich visual effect. During the punching process, attention should be paid to ensuring the accuracy of the size and position of the holes to ensure the aesthetics and practicality of the punched ceiling aluminum veneer.

3. Surface treatment

Punched ceiling aluminum veneer requires surface treatment technology to achieve better performance. Usually, surface treatment processes such as anodizing and electrophoretic coating are used to enhance the corrosion resistance and oxidation resistance of aluminum veneer, thereby improving its service life.

4. Installation and maintenance

After completing the production of perforated ceiling aluminum veneer, installation and maintenance work are required. Attention should be paid to the position and fixing method of the aluminum veneer during installation to ensure its stability and safety. Attention should be paid to keeping the aluminum veneer clean and moisture-proof during maintenance to avoid damage or corrosion.

3、 Summary

Punched ceiling aluminum veneer, as a new type of building material, both its material and process are very important. By introducing its materials and processes, we can better understand its characteristics and advantages. In the future, with the continuous advancement and innovation of technology, perforated ceiling aluminum veneer will become more mature and perfect, bringing more new opportunities and challenges to the building decoration industry.

Customer service QQ

Customer service QQ