Industry information

Company News

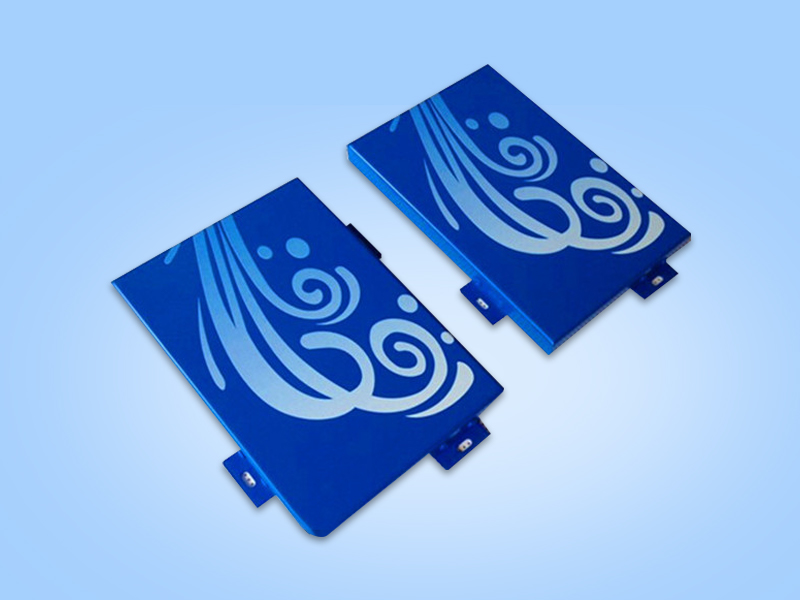

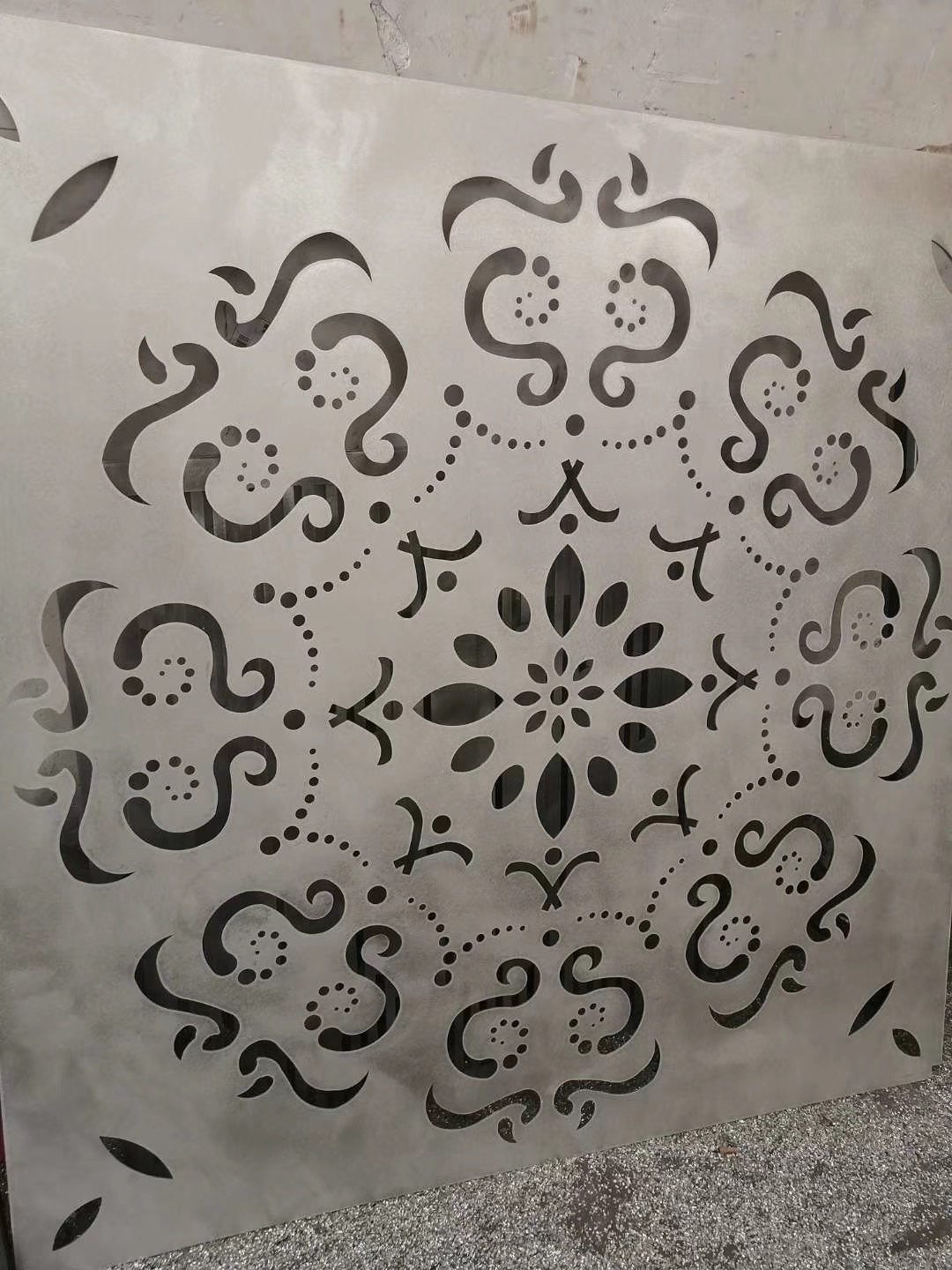

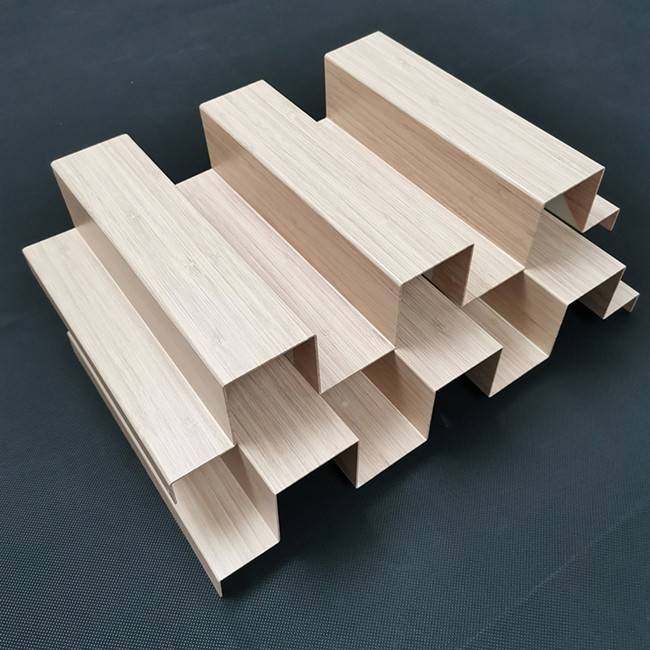

- Ceiling aluminum veneer: the beauty of aluminum, the charm of space

- Ceiling aluminum veneer, the perfect combination of fashion and texture!

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer: not just decoration, but also a bridge of art!

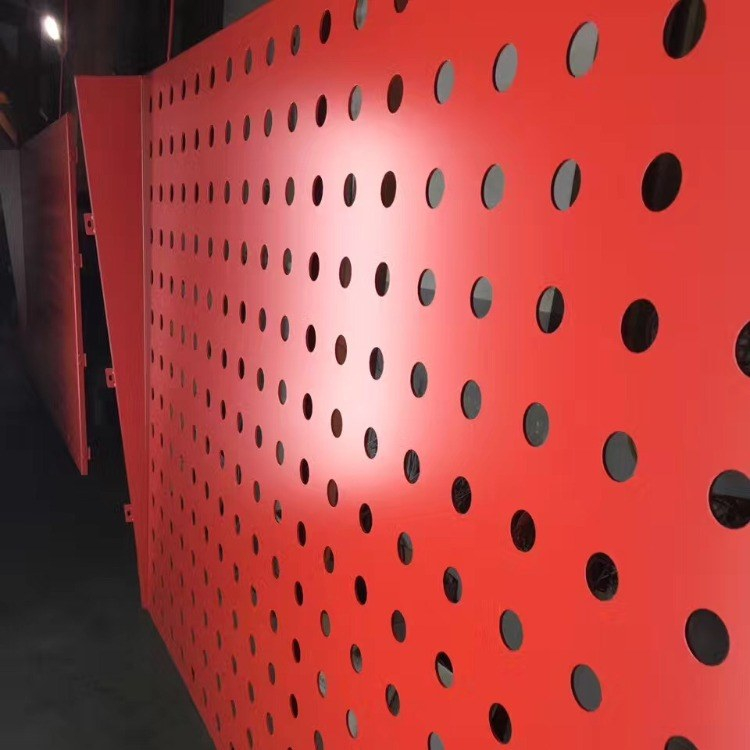

- Aluminum veneer for exterior walls, creating a modern architectural style

Industry dynamics

- Aluminum veneer safety standards are fully guaranteed!

- Detailed explanation of customized services provided by aluminum veneer manufacturers

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Production cost and price trend of aluminum veneer

- What is the impact resistance of aluminum veneer?

Frequently asked questions

- How to store and transport aluminum veneer correctly?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to choose high-quality aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Mechanical performance evaluation of 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 14, 2025 17:41:08

- Click:0

1.5mmAluminum veneerIt is a common building material, and its mechanical properties have a significant impact on the overall stability and safety of buildings. This article will provide a detailed introduction to the mechanical performance evaluation of 1.5mm aluminum veneer.

In terms of material properties, 1.5mm thick aluminum veneer usually has good strength and stiffness, and can withstand certain loads and deformations. Aluminum veneer also has good plasticity and processability, and can achieve various complex shapes and structures.

To evaluate the mechanical properties of 1.5mm aluminum veneer, the following steps need to be taken:

1. Determine testing parameters: Based on the actual application situation, determine the mechanical parameters that need to be tested, including tensile strength, yield strength, elastic modulus, etc.

2. Conduct experiments: Place 1.5mm aluminum veneer in the laboratory and test it through stretching, compression, and other methods. Other testing equipment such as universal testing machines can also be used for more accurate testing.

3. Analysis results: Based on experimental data, the mechanical performance parameter values of aluminum veneer can be calculated. If these parameter values exceed the specified standard values, it indicates that the mechanical properties of the aluminum veneer are not good enough and corresponding measures need to be taken to improve them.

In addition to the basic testing parameters mentioned above, the following points should also be noted:

When conducting mechanical performance testing, it is necessary to pay attention to the influence of environmental factors such as temperature and humidity to avoid interference with the test results.

For different types of aluminum veneers, their mechanical performance parameters may vary, so it is necessary to choose appropriate testing methods and parameters according to specific situations.

When conducting mechanical performance testing, it is necessary to pay attention to safety issues and avoid accidents.

The mechanical performance evaluation of 1.5mm thick aluminum veneer is a very important task that can help us understand its stability and safety in practical applications. In practical applications, appropriate measures should be taken according to specific situations to improve its mechanical properties and service life.

Customer service QQ

Customer service QQ