Industry information

Company News

- Aluminum veneer: the 'invisible hero' of modern architecture

- Aluminum veneer: the 'invisible hero' of modern architecture

- Ceiling aluminum veneer: a perfect combination of fashion and practicality

- Ceiling aluminum veneer: a perfect fusion of fashion and practicality

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Analysis of the Development Trend of Ceiling Roller Coated Aluminum Veneer Industry

- Aluminum veneer for exterior walls, fashionable new clothes for buildings

- New favorite of ceiling - Aluminum veneer style

- Aluminum veneer: a low-key aristocrat in modern architecture

- Selection and use of high-quality perforated aluminum veneer for curtain wall materials

Frequently asked questions

- How to improve the environmental performance of aluminum veneer?

- How to choose the most suitable aluminum veneer material?

- What is aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The history and development trend of 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 15, 2025 01:56:52

- Click:0

1.5mmAluminum veneerIt is a common building material with a history dating back to the 1970s. With the continuous advancement of construction technology and people's pursuit of architectural aesthetics, 1.5mm aluminum veneer has gradually become a popular decorative material. This article will provide a detailed introduction to the history and development trends of 1.5mm aluminum veneer.

In the 1970s, with the rapid development of industrial technology, aluminum began to be widely used in the field of construction. The initial aluminum veneer was mainly processed from aluminum alloy sheets, which had good strength and stiffness, but were heavy and costly. Later, with the improvement of production processes and the emergence of new materials, 1.5mm thick aluminum veneer gradually replaced traditional aluminum alloy sheets. In contrast, aluminum veneer with a thickness of 1.5mm is not only lighter in weight and lower in cost, but also has good plasticity and processability, which can achieve various complex shapes and structures.

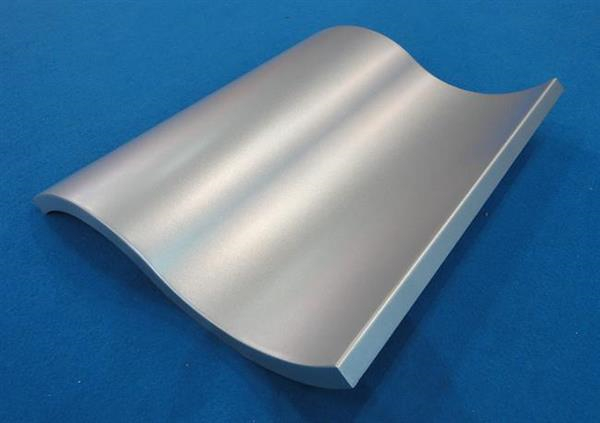

In the past few decades of development, 1.5mm aluminum veneer has undergone multiple technological innovations and product upgrades. For example, early 1.5mm aluminum veneers mainly used surface treatment processes such as spraying and rolling, while today's 1.5mm aluminum veneers use more advanced processes such as electrophoretic coating and anodizing, making the surface of the aluminum veneer smoother, corrosion-resistant, and easier to clean. With the increasing demand for environmental protection and energy conservation, some new materials such as carbon fiber reinforced plastic (CFRP) have also been applied in the production of 1.5mm aluminum veneer.

In the future development, 1.5mm aluminum veneer still has great potential for growth. On the one hand, with the continuous improvement of people's requirements for architectural aesthetics, 1.5mm aluminum veneer can meet the needs of different places through different surface treatment processes and color choices. On the other hand, with the continuous development of new energy technology, 1.5mm aluminum veneer can also be applied in fields such as solar panels and wind turbines, exerting its excellent thermal and electrical conductivity.

1.5mm aluminum veneer, as a common building material, has a history dating back to the 1970s. With the continuous advancement of technology and people's pursuit of architectural aesthetics, 1.5mm aluminum veneer has become a popular decorative material. In the future development, 1.5mm aluminum veneer will continue to exert its excellent performance characteristics and make greater contributions to the development of the construction field.

Customer service QQ

Customer service QQ