Industry information

Company News

- Ceiling aluminum veneer, a new favorite in home decor, perfectly combines aesthetics and practicality!

- Aluminum veneer for exterior walls: a fashionable outerwear for modern architecture

- Aluminum veneer: the new darling of the construction industry, revealing its charm!

- Ceiling aluminum veneer, a fashionable choice for modern home decor!

- The Charm of Aluminum Veneer: The 'Invisible Hero' of Modern Architecture

Industry dynamics

- Is the frequency of use of aluminum veneer high?

- Characteristics and Applications of Colored Perforated Aluminum Veneer

- Aluminum veneer for exterior walls: creating a fashionable outerwear for modern architecture

- The performance of aluminum veneer in insulation and heat preservation

- Fluorocarbon aluminum veneer: the "invisible garment" of fashionable architecture

Frequently asked questions

- How to extend the service life of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to choose the most suitable aluminum veneer material?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Material source and production process of 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 16, 2025 13:36:37

- Click:0

1.5mmAluminum veneerIt is a very common building material, and its material source and production process are crucial for ensuring the safety and aesthetics of buildings. This article will provide a detailed introduction to the material sources and production processes of 1.5mm aluminum veneer.

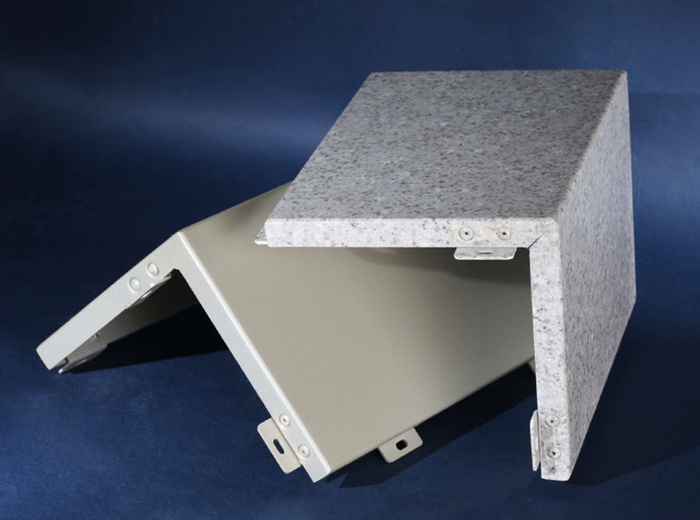

In terms of material sources, 1.5mm aluminum veneer usually uses high-quality aluminum alloy materials. This material has high strength and corrosion resistance, as well as good plasticity and processability. Aluminum alloy materials usually come from the mining and smelting process of bauxite, and undergo a series of process treatments such as electrolysis, melting, casting, etc., ultimately forming various shapes and specifications required for aluminum veneer.

In terms of production technology, 1.5mm aluminum veneer is usually produced using rolling and spraying processes. Rolling is the process of processing aluminum alloy materials through a continuous rolling mill to achieve the desired thickness and width. Spraying is the process of applying a dense oxide film onto pre treated aluminum alloy materials to enhance their corrosion resistance and decorative effect. Surface treatment can also be carried out as needed, such as anodizing, electroplating, etc., to further improve the performance and aesthetics of aluminum veneer.

Again, it is necessary to pay attention to some quality control and environmental protection measures during the production process. For example, strict screening and testing of raw materials are required to ensure their quality meets the requirements; Regular maintenance and upkeep of production equipment are required to ensure its normal operation; At the same time, a series of environmental protection measures need to be taken, such as reducing exhaust emissions, wastewater treatment, etc., to protect the environment and human health.

In terms of quality inspection and acceptance, it is also necessary to inspect and evaluate the material and production process of aluminum veneer. During this process, it is necessary to pay attention to factors such as the dimensional accuracy, surface smoothness, and color uniformity of the aluminum veneer to ensure that its quality meets the requirements.

The material source and production process of 1.5mm aluminum veneer are one of its very important advantages. In practical applications, attention should be paid to the quality and effectiveness of the selected materials to ensure better decorative and usage effects, while also paying attention to the production process and environmental protection measures of the materials.

Customer service QQ

Customer service QQ