Industry information

Company News

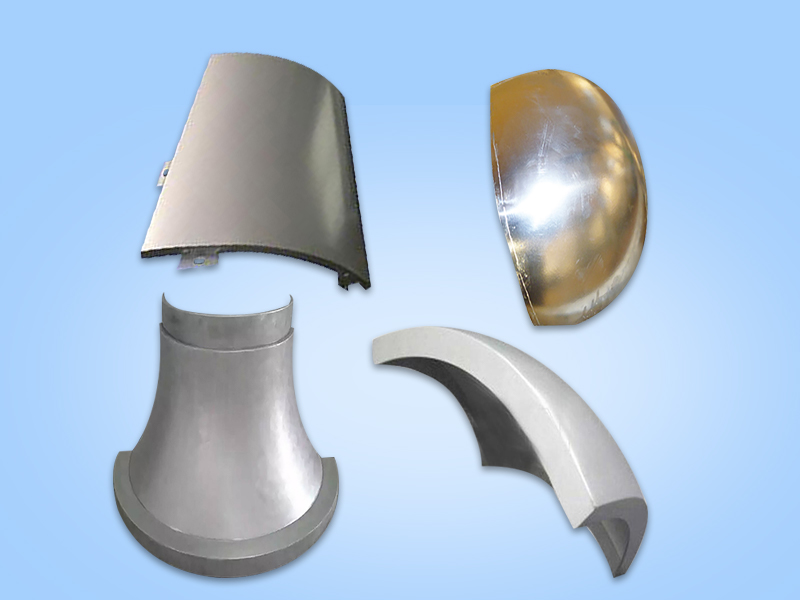

- Aluminum veneer: the secret weapon for creating a new style of modern architecture

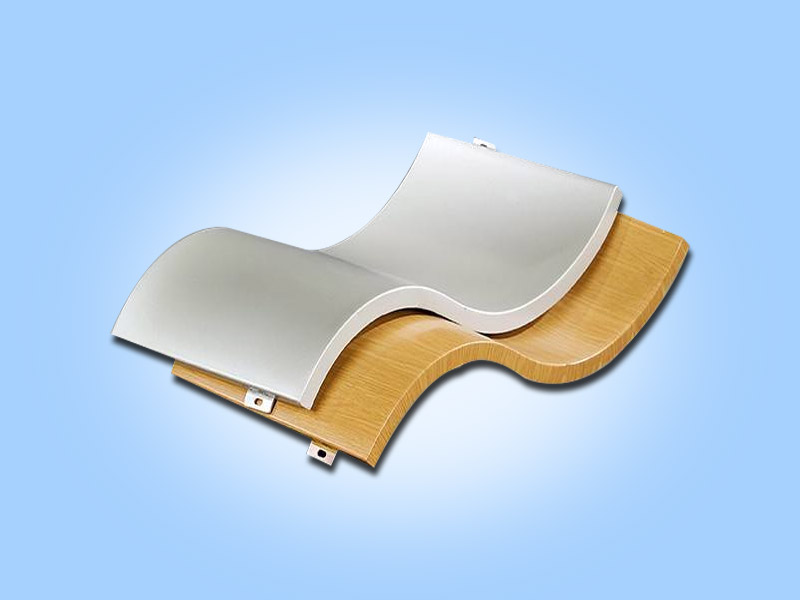

- Aluminum veneer ceiling, light luxury and simple new style

- Aluminum ceiling, a fashionable choice for modern home decor!

- Aluminum veneer ceiling: the new favorite of modern home decor, creating fashionable spaces

- Aluminum veneer: the new favorite in the construction industry, revealing its charm!

Industry dynamics

- Production process and quality control of 2.5mm painted aluminum veneer

- Ceiling aluminum veneer: the fashionable "coat" of modern architecture

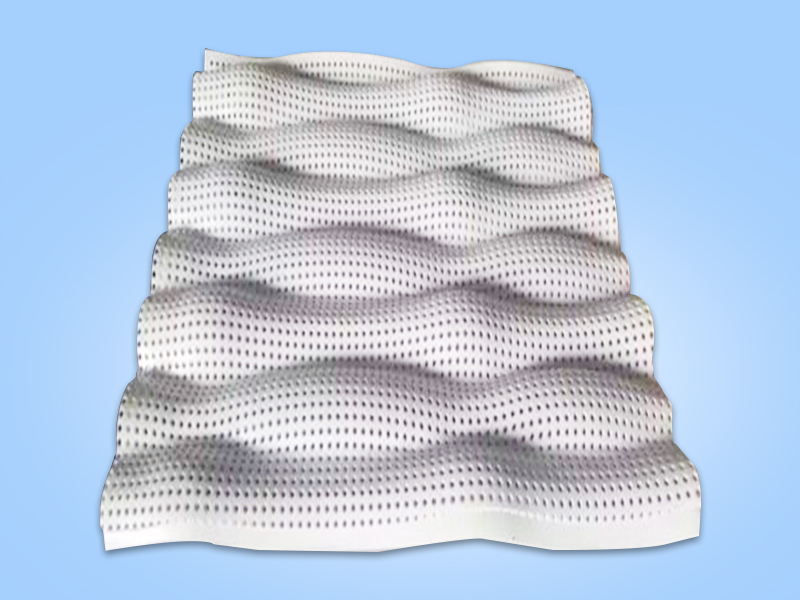

- Design and decorative effect of perforated carved aluminum veneer

- Aluminum veneer: the "invisible master" of modern architecture

- Environmental performance analysis of carved aluminum veneer

Frequently asked questions

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to choose high-quality aluminum veneer?

- How to extend the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Corrosion resistance testing of aluminum veneer and its role in construction

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 8, 2025 01:50:55

- Click:0

Aluminum veneerIt is a common building material with advantages such as lightweight, high strength, and corrosion resistance. Aluminum veneer is widely used in various fields such as curtain walls, roofs, and walls in architecture. The corrosion resistance of aluminum veneer is one of the important factors that contribute to its use in construction. This article will introduce the corrosion resistance testing method of aluminum veneer and its role in construction.

1、 Testing method for corrosion resistance of aluminum veneer

1. Salt spray test method

The salt spray test method is a commonly used method for testing the corrosion resistance of aluminum veneer. This method evaluates the corrosion resistance of aluminum veneer samples by placing them in saltwater, simulating changes in humidity and temperature in the atmosphere, and observing whether there is corrosion on the surface of the aluminum veneer. Generally speaking, the salt spray test method can be divided into three levels: NSS (non oxidizing), CASS (acidic), and BASS (alkaline). The NSS level indicates that the aluminum veneer did not show any corrosion during the salt spray test, making it the most excellent corrosion resistance level.

1. Electrochemical testing method

Electrochemical testing method is a relatively complex method for testing the corrosion resistance of aluminum veneer. This method evaluates the potential difference and current density on the surface of aluminum veneer through electrolytic reaction, in order to determine the corrosion resistance of aluminum veneer. The electrochemical testing method can measure parameters such as the thickness, porosity, and crystal structure of the oxide film on the surface of aluminum veneer, providing more accurate data for evaluating the corrosion resistance of aluminum veneer.

2、 The role of aluminum veneer in construction

1. Curtain wall application

Aluminum veneer, as one of the main materials for curtain walls, has the advantages of light weight, high strength, and corrosion resistance. In high-rise buildings, the application of curtain walls is becoming increasingly widespread, and aluminum veneer, as one of the main materials for curtain walls, has particularly important corrosion resistance performance. Only aluminum veneers with good corrosion resistance can ensure the long-term stable operation of curtain walls, while also reducing maintenance and replacement costs.

1. Roof application

In the field of roofing, aluminum veneer also has a wide range of applications. Compared with traditional concrete or metal roofs, aluminum veneer has the advantages of light weight, easy construction, and low maintenance costs. And its good corrosion resistance can ensure that aluminum veneer will not rust or other problems during long-term use, extending its service life.

The corrosion resistance test of aluminum veneer is one of the important means to evaluate its quality and reliability. In the field of architecture,

Customer service QQ

Customer service QQ