Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Ceiling aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum veneer: a fashionable outerwear for industrial buildings

- Aluminum veneer: the 'invisible hero' of modern architecture

- The fashion revolution of aluminum veneer reveals the charm of exterior aluminum veneer!

Industry dynamics

- Aluminum veneer: understated luxury in modern architecture

- Fluorocarbon aluminum veneer: the new favorite of aluminum materials, a new choice for the beauty of architecture

- Fluorocarbon aluminum veneer: a perfect combination of fashion and durability

- The secret of ceiling aluminum veneer reveals the elegant guardian of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How to choose to purchase high-quality aluminum veneer?

- How to choose high-quality aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

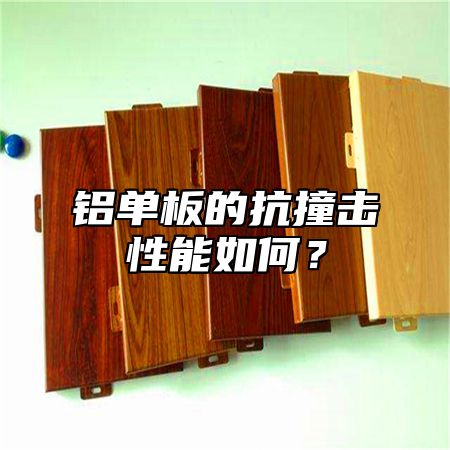

What is the impact resistance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 9, 2025 15:15:16

- Click:0

Aluminum veneerAs a new type of building material, its impact resistance has attracted much attention. Let's take a look at the impact resistance performance of aluminum veneer together.

The material of aluminum veneer has an impact on its impact resistance performance. Generally speaking, pure aluminum has poor impact resistance, while some alloy materials, such as aluminum alloys, magnesium alloys, etc., have good impact resistance. These alloy materials have added some special elements such as lithium, zirconium, copper, etc. during the manufacturing process, which can effectively improve their hardness and strength, thereby enhancing their impact resistance.

The surface treatment of aluminum veneer also affects its impact resistance performance. Some surface treatment techniques can form a protective film to prevent aluminum veneer from being damaged by factors such as oxidation, corrosion, and high temperature, thereby improving its impact resistance. For example, anodizing treatment can form an oxide film, improving the wear resistance and corrosion resistance of aluminum veneer; Fluorocarbon coatings can form a waterproof, anti fouling, and high-temperature resistant coating to protect aluminum veneers from external environmental influences.

The use and maintenance of aluminum veneer can also improve its impact resistance performance. During use, attention should be paid to avoiding adverse effects such as scratching, impact, and contamination on the aluminum veneer, in order to prevent damage to its surface protective layer or internal structure. Regular cleaning and maintenance are also necessary to maintain its surface smoothness and aesthetics, and extend its service life. During installation and use, it is necessary to comply with relevant fire regulations and safety operating procedures to ensure the safety and stability of aluminum veneer.

It should be noted that the impact resistance of aluminum veneer is also affected by factors such as climate and environment. For example, in adverse weather or high-risk environments, aluminum veneer is susceptible to impact and damage, thereby reducing its impact resistance. When selecting aluminum veneer, it is necessary to consider and choose according to specific climate and environmental conditions to ensure that it can adapt to the local natural environment.

The impact resistance of aluminum veneer is mainly reflected in its material, surface treatment, use, and maintenance. By selecting appropriate materials, surface treatment methods, usage and maintenance methods, and complying with relevant fire regulations and safety operating procedures, the impact resistance of aluminum veneer can be maximized, providing users with safer and more reliable products and services.

Customer service QQ

Customer service QQ