Industry information

Company News

- Aluminum veneer: the new darling of the construction industry, revealing its charm!

- Aluminum veneer exterior wall, the fashionable coat of modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer for exterior walls, the fashionable choice for modern architecture?

- Ceiling aluminum veneer: a perfect combination of fashion and practicality!

Industry dynamics

- " Aluminum veneer ceiling, revealing the new fashion of modern home furnishings& quot;}

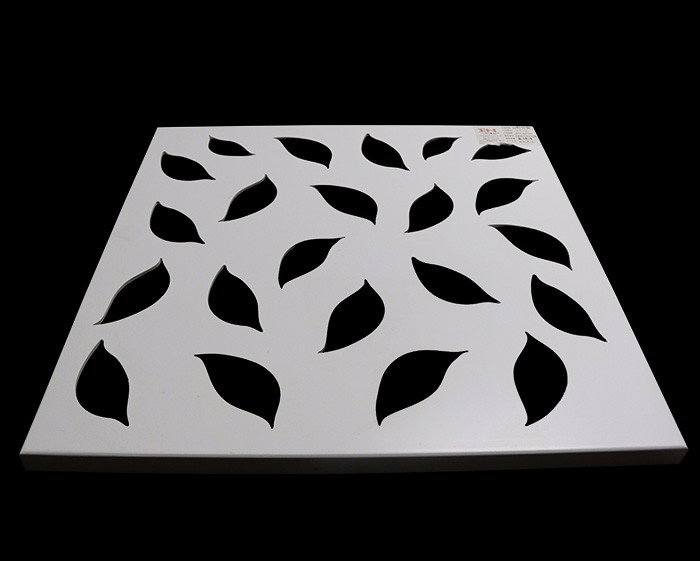

- Hollow aluminum veneer breaks through the boundaries of traditional architecture

- New trend ceiling aluminum veneer, creating the new favorite of fashionable spaces!

- Aluminum veneer ceiling, creating a new height for home decor!

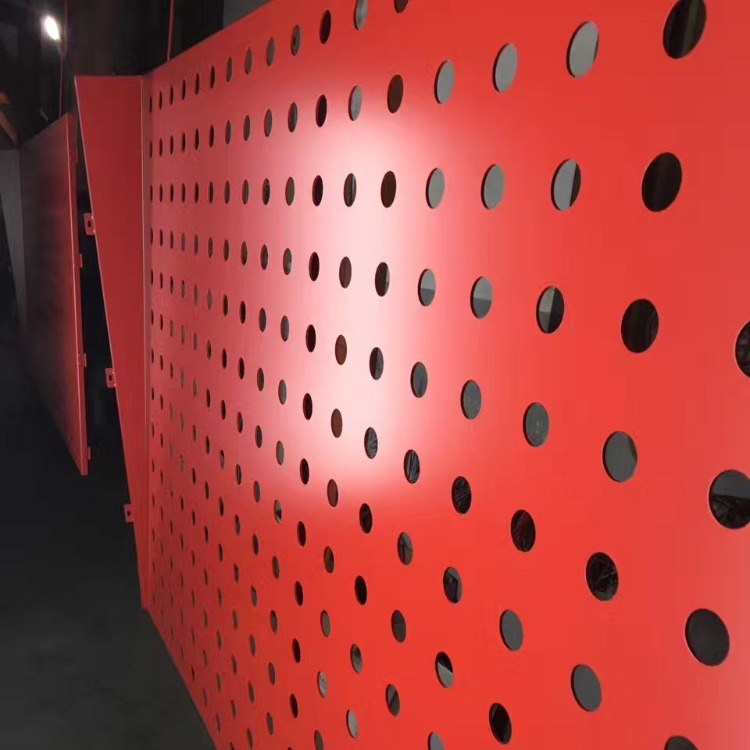

- Can't you think of it? Punched aluminum veneer can be used like this!

Frequently asked questions

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the new technologies for surface treatment of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-07 05:57:59

- Click:0

Aluminum veneerAs a new type of building material, its surface treatment technology is constantly innovating and developing. Next, we will provide a detailed introduction to the new surface treatment technology for aluminum veneer.

1. Anodizing

Anodizing is a common surface treatment technique for aluminum veneer, which can improve its hardness, wear resistance, and corrosion resistance. By subjecting aluminum veneer to electrolytic oxidation treatment in an electrolyte solution, a dense oxide film can be formed to protect the surface of the aluminum veneer from external environmental influences. Anodizing can also achieve dyeing and printing of various colors and patterns, providing more possibilities for the application of aluminum veneer.

1. Spray coating

Spray coating is a commonly used surface treatment technique for aluminum veneer, which can achieve decorative effects in various colors and patterns. By spraying paint onto the surface of aluminum veneer, a uniform coating can be formed, thereby enhancing the decorative and aesthetic appeal of the aluminum veneer. Spraying can also achieve printing and carving of various colors and patterns, providing more choices for the application of aluminum veneer.

1. Fluorocarbon spraying

Fluorocarbon spraying is a high-end surface treatment technology for aluminum veneer, which has excellent weather resistance and corrosion resistance. By spraying fluorocarbon coating on the surface of aluminum veneer, a hard, smooth, and uniform coating can be formed, thereby improving the decorative and service life of aluminum veneer. Fluorocarbon spraying can also achieve dyeing and printing of various colors and patterns, providing more creative space for the application of aluminum veneer.

1. Heat transfer printing

Heat transfer printing is an emerging surface treatment technology for aluminum veneer, which can directly transfer patterns and text onto the aluminum veneer. By heating and transferring patterns or text onto special paper, and then sticking the paper onto the surface of aluminum veneer, high-quality pattern and text printing effects can be achieved. Heat transfer printing can also achieve printing and engraving of multiple colors and patterns, providing more flexibility and creative space for the application of aluminum veneer.

The surface treatment technology of aluminum veneer is constantly innovating and developing, providing users with more diversified and personalized products and services. Through various surface treatment techniques such as anodizing, spraying, fluorocarbon spraying, and heat transfer printing, the decorative, durability, and applicability of aluminum veneer can be improved to meet the needs of different occasions. These new technologies can also reduce production costs and environmental pollution, contributing to sustainable development.

Customer service QQ

Customer service QQ