Industry information

Company News

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum veneer for exterior walls: the "fashionable coat" of modern architecture

- Ceiling aluminum veneer: the new aesthetic favorite of modern architecture

- Aluminum veneer for exterior walls, the new fashionable outerwear of modern architecture

- Aluminum veneer: not only for walls, but also a perfect combination of fashion and durability!

Industry dynamics

- Exploration into the Market Prospects of Aluminum Veneer

- What are the innovative effects of aluminum veneer in architectural exterior design?

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum veneer ceiling: the new darling of creating fashionable spaces

- Aluminum veneer: the 'hidden hero' of modern architecture

Frequently asked questions

- How to choose high-quality aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

- How to extend the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

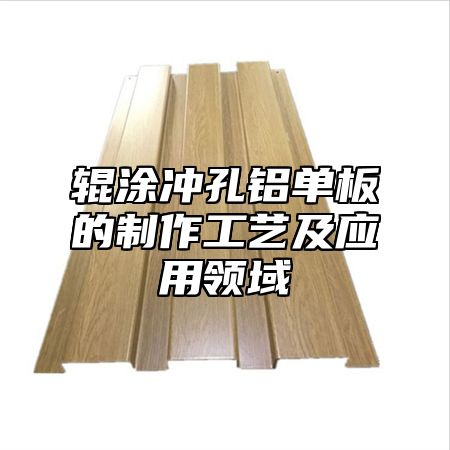

Manufacturing process and application fields of roll coated punched aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-18 16:44:53

- Click:0

Roll coating punchingAluminum veneerIt is an aluminum veneer with a special pore structure, and its manufacturing process is more complex compared to traditional aluminum veneers. This article will provide a detailed introduction to the manufacturing process and application areas of roll coated punched aluminum veneer.

1、 Production process

1. Material preparation

The materials for roll coated punched aluminum veneer mainly include aluminum alloy sheets, punching molds, coatings, etc. Aluminum alloy sheet is the main material for roll coated punched aluminum veneer, with a thickness of generally 1.5mm-3mm and a width of generally 1200mm-2400mm. Punching molds are made according to design requirements and can be processed using CNC machine tools. Coatings should be selected that are compatible with aluminum alloys and have good corrosion resistance and adhesion.

1. Pre treatment process

Before roller coating, it is necessary to perform a pre-treatment process on the aluminum alloy sheet to remove impurities such as oxide layers and oil stains on the surface, ensuring the quality and adhesion of the coating. The pre-treatment process includes acid washing, alkali washing, polishing and other steps, among which acid washing is the most critical step, which can effectively remove the oxide layer and oil stains.

1. Primer spraying

Before roller coating, it is necessary to spray a layer of primer to enhance the adhesion and bonding between the coating and the surface of the aluminum alloy sheet. The primer should be selected with a coating suitable for the aluminum alloy material and sprayed in a certain proportion and method.

1. Topcoat spraying

Topcoat is the most critical step in roll coating punched aluminum veneer, which directly affects the appearance and anti-corrosion performance of the aluminum veneer. The topcoat should be selected with a coating suitable for the aluminum alloy material and sprayed in a certain proportion and method. When spraying topcoat, the following points should be noted:

(1) The spraying distance should be controlled between 10-20cm to ensure the uniformity and thickness of the coating;

(2) The spraying angle should be controlled at around 45 degrees to ensure that the coating can fully cover the entire surface of the aluminum veneer;

(3) The spraying frequency generally needs to be more than two times to achieve good adhesion and anti-corrosion effect.

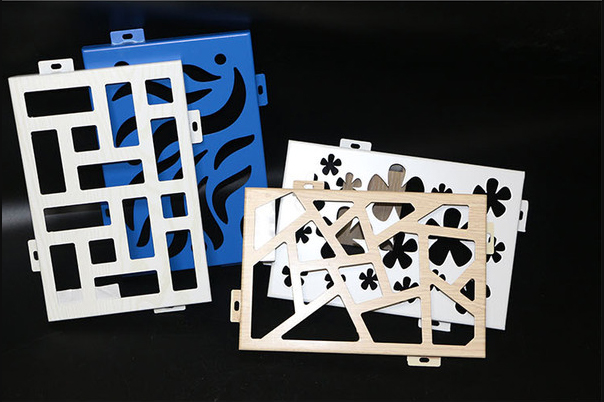

1. Punching process

After completing the topcoat spraying, a punching process is required to form the desired hole structure. The punching process can be processed using CNC punching machines or laser punching machines, and the size and shape of the punching can be adjusted according to design requirements.

1. Baking and curing

Baking curing is the final step in roll coated punched aluminum veneer, which can make the coating harder, more stable, and durable. The baking temperature and time should be adjusted according to the specific requirements of the coating, generally controlled between 80-120 ° C for about 20-30 minutes. Attention should be paid to avoiding excessive baking or incomplete curing.

2、 Application Fields

Customer service QQ

Customer service QQ