Industry information

Company News

- Aluminum veneer ceiling: a work of art that combines fashion and practicality

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum veneer: the new favorite of the construction industry, the perfect combination of fashion and practicality

- Fluorocarbon aluminum veneer: a new favorite in architecture, perfectly integrating fashion and durability

Industry dynamics

- Ceiling carved aluminum veneer made of environmentally friendly materials

- Aluminum veneer for exterior walls: the "fashionable coat" of urban architecture

- Aluminum veneer adds charm to buildings

- Aluminum veneer ceiling: creating a new trend of modern home decor

- Production process and quality control of 2.5mm painted aluminum veneer

Frequently asked questions

- How to choose the most suitable aluminum veneer material?

- How to improve the sound insulation performance of aluminum veneer?

- What is aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to improve the corrosion resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

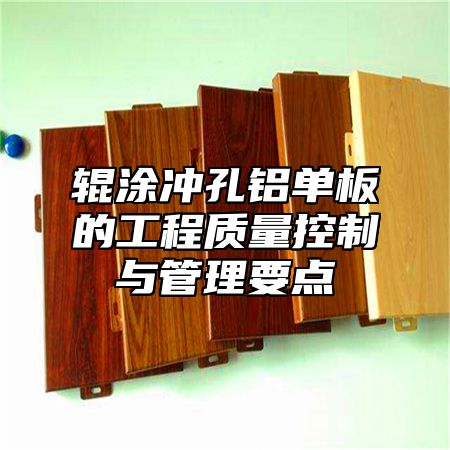

Key points for engineering quality control and management of roll coated punched aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-15 17:55:50

- Click:0

Roll coating punchingAluminum veneerAs a new type of building decoration material, its quality control and management are of great significance for ensuring project quality and safety. This article will provide a detailed introduction to the engineering quality control and management points of roll coated punched aluminum veneer from the aspects of materials, processes, equipment, personnel, etc.

1、 Materials

1. Selection of raw materials: High quality aluminum alloy materials that meet national standards should be selected to ensure their strength and corrosion resistance.

2. Material inspection: Strict inspections should be conducted on the purchased materials, including chemical composition, mechanical properties, surface treatment, and other items, to ensure that the materials meet the design requirements.

2、 Craftsmanship

1. Pre treatment process: Advanced pre-treatment processes such as acid washing, alkali washing, polishing, etc. should be used to remove surface oxide layers and impurities such as oil stains, improve coating adhesion and anti-corrosion performance.

2. Spraying process: Efficient spraying processes such as roller coating, electrostatic spraying, etc. should be used to ensure that the coating is uniform, flat, and the thickness meets the design requirements.

3、 Equipment

1. Spraying equipment: Efficient and stable spraying equipment should be selected, such as roller coating machines, electrostatic spraying machines, etc., to ensure stable spraying efficiency and quality.

2. Baking equipment: Professional baking equipment such as electric furnaces, ovens, etc. should be selected to ensure that the coating curing temperature and time meet the design requirements.

4、 Personnel

1. Operators: They should receive professional training, master the spraying process and operational skills, and ensure standardized and safe operation.

2. Quality inspectors: Professional quality inspectors should be equipped to conduct strict inspections and tests on materials and finished products to ensure that product quality meets standards.

5、 Management points

1. Develop a detailed construction plan: Based on the design plan and construction conditions, develop a detailed construction plan, clarify each process and responsible person.

2. Strengthen on-site management: Strengthen on-site management to ensure safety and quality during the construction process, and prevent quality problems caused by human factors.

3. Establish a quality management system: Establish a comprehensive quality management system, including quality inspection system, quality feedback mechanism, etc., to ensure the stability and continuous improvement of product quality.

The engineering quality control and management of roll coated punched aluminum veneer is a key link to ensure product quality and safety. Through reasonable material selection, scientific process flow, advanced equipment configuration, and professional personnel management, the engineering quality and competitiveness of roll coated punched aluminum veneer can be effectively improved.

Customer service QQ

Customer service QQ