Industry information

Company News

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer customization: infinite possibilities for personalized space

- Aluminum veneer for exterior walls: a fashionable outerwear for modern architecture

- Aluminum veneer for exterior walls, the "fashionable outerwear" of the construction industry

Industry dynamics

- Aluminum veneer: the fashionable choice for modern architecture

- The production process and technology of artistic curtain wall aluminum veneer

- Aluminum veneer ceiling: a shining pearl in modern architecture

- How much do you know about aluminum veneer for exterior walls: the fashionable outerwear of architecture?

- Comparison of aluminum veneer prices with other materials

Frequently asked questions

- How to improve the wind resistance performance of aluminum veneer?

- How to choose the most suitable aluminum veneer material?

- How to improve the corrosion resistance of aluminum veneer?

- What is aluminum veneer?

- How to store and transport aluminum veneer correctly?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Corrosion resistance of 2.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-17 18:12:21

- Click:0

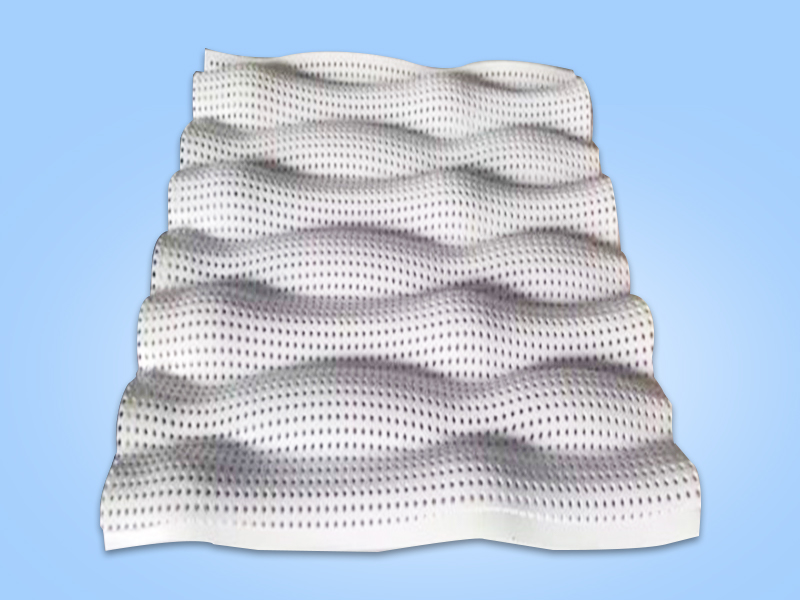

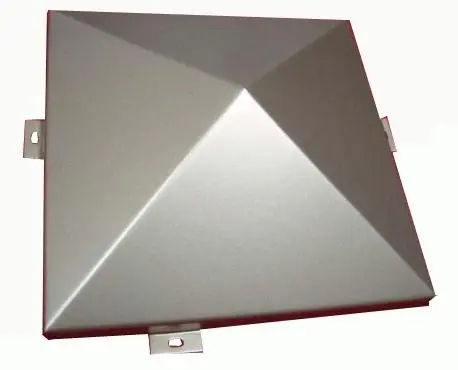

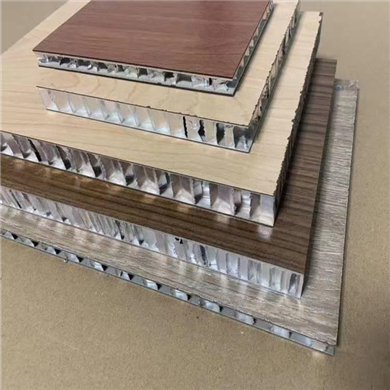

Aluminum veneerIt is a lightweight, weather resistant, fire-resistant, and corrosion-resistant building material that has a wide range of applications in architectural decoration. 2.5mm thick aluminum veneer is a common specification with high strength and stability, suitable for various building applications. This article will provide a detailed introduction from multiple aspects to answer the question of the anti-corrosion performance of 2.5mm aluminum veneer.

The anti-corrosion performance of 2.5mm thick aluminum veneer mainly depends on its surface treatment method and material quality. Generally speaking, aluminum veneers treated with surface treatments such as anodizing or spraying have better anti-corrosion properties and can effectively prevent aluminum veneers from being affected by factors such as oxidation, corrosion, and ultraviolet radiation; Using high-quality materials to produce aluminum veneer can also improve its anti-corrosion performance.

The anti-corrosion performance of 2.5mm thick aluminum veneer is also related to its usage environment. For example, aluminum veneer used in humid and highly corrosive environments needs to have better anti-corrosion performance to ensure its service life and stability. During use, it is also necessary to avoid external impact or damage to the aluminum veneer to avoid affecting its anti-corrosion performance.

Thirdly, the anti-corrosion performance of 2.5mm thick aluminum veneer can be improved through regular maintenance and upkeep. For example, regularly cleaning and painting the surface of aluminum veneer can maintain its surface smoothness and aesthetics, while also extending its service life; Aluminum veneer can also undergo anti-corrosion treatment, such as brushing with anti-corrosion coatings, to improve its anti-corrosion performance.

It should be noted that the anti-corrosion performance of 2.5mm thick aluminum veneer needs to be tested and evaluated by professionals. Only through professional testing and evaluation can the anti-corrosion performance of aluminum veneer be determined to meet relevant requirements and standards, thereby ensuring its reliability and safety in practical use.

The anti-corrosion performance of 2.5mm thick aluminum veneer is a process that requires comprehensive consideration of multiple factors. By selecting appropriate surface treatment methods, high-quality materials, paying attention to the usage environment, regular maintenance and upkeep, and professional testing and evaluation, the anti-corrosion performance of aluminum veneer can be ensured to reach the best state. When designing building decoration materials, it is necessary to choose suitable materials and design schemes according to specific situations to ensure the quality and stability of the overall decoration effect.

Customer service QQ

Customer service QQ