Industry information

Company News

- Ceiling aluminum veneer, creating a new choice for fashionable home decor!

- Unveiling the Charm of Aluminum Veneer: The New Fashion Favorite in Architecture

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics?

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer: the 'invisible hero' of modern architecture

Industry dynamics

- Customized aluminum veneer to create your own unique aesthetic space

- Performance and advantages analysis of twisted 1.5mm aluminum veneer

- Ceiling aluminum veneer: a magnificent transformation of spatial art

- Aluminum veneer new trend, new choice for home decoration

- High strength building ceiling aluminum veneer brings more choices to buildings

Frequently asked questions

- How to improve the environmental performance of aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to choose the most suitable aluminum veneer material?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and quality control of 2.5mm painted aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-18 20:04:03

- Click:0

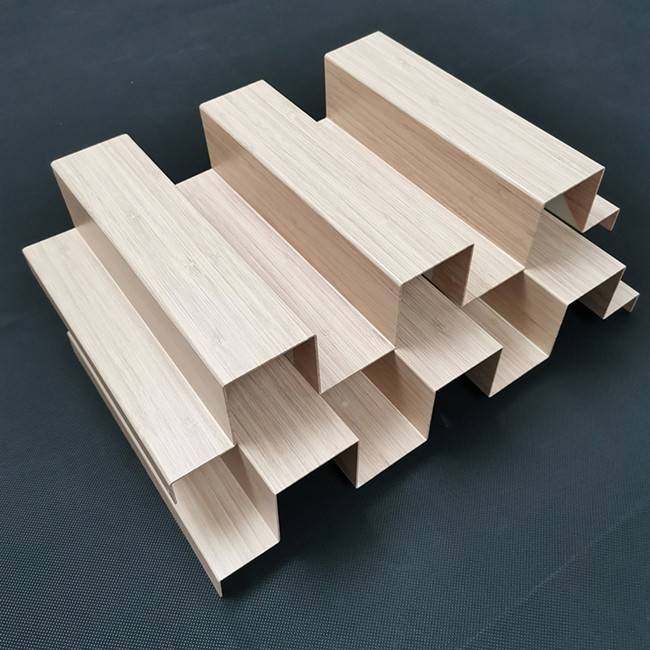

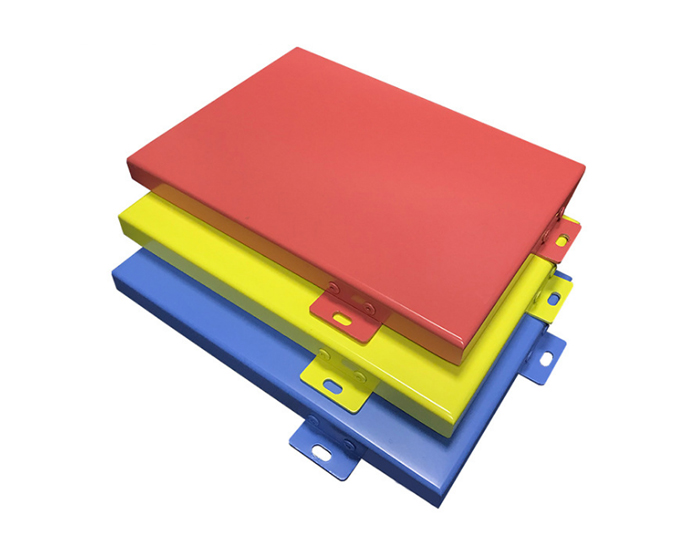

2.5mm baking paintAluminum veneerIt is a high-end building decoration material, and its production process and quality control are very important. Below is a detailed introduction to the production process and quality control of 2.5mm painted aluminum veneer.

1、 Production process

1. Raw material procurement

2. Cutting and processing

3. Polishing treatment

4. Surface spraying

5. Paint treatment

2、 Quality control

1. Quality control of raw materials

2. Quality control in the production process

3. Finished product quality inspection

3、 Production Process Flow Chart

(omitted)

4、 Quality Control Flow Chart

(omitted)

5、 Precautions

1. In the process of raw material procurement, high-quality aluminum alloy materials should be selected to ensure product quality.

2. Pay attention to safety in the cutting and processing process to avoid personal injury and equipment damage.

3. Suitable tools and methods should be used in the polishing process to ensure surface smoothness and flatness.

4. During the surface spraying and baking treatment, it is necessary to strictly follow the process requirements to avoid color difference and uneven coating.

5. In the finished product quality inspection process, strict testing should be carried out in accordance with national standards to ensure that the product quality meets the requirements.

6、 Summary

The production process and quality control of 2.5mm painted aluminum veneer are key to ensuring product quality. Only by strictly controlling every step can we produce high-quality 2.5mm painted aluminum veneer that meets the needs and expectations of our customers. Enterprises should strengthen technology research and quality management, improve production efficiency and product quality, and provide better products and services to the market.

- previous page:Application areas of 2.5mm carved aluminum veneer

- Next page:Corrosion resistance of 2.5mm aluminum veneer

Customer service QQ

Customer service QQ