Industry information

Company News

- Aluminum veneer for exterior walls: the charm of modern architecture's "coat"

- Customized aluminum veneer, creating a new concept of personalized space!

- Exploring the Hidden Aesthetics of Aluminum Veneers in Modern Architecture

- Aluminum veneer: the 'invisible hero' of modern architecture?

- Ceiling aluminum veneer: the new favorite of aluminum materials and the fashionable choice for modern architecture

Industry dynamics

- Ceiling aluminum veneer, modern home new fashion!

- " Ceiling aluminum veneer, the secret weapon of fashion and new trends& quot;}

- Professional manufacturing of 3mm brushed aluminum veneer products

- Fluorocarbon aluminum veneer: a fashion icon in the aluminum industry, your new choice for architectural aesthetics!

- Aluminum veneer has long-lasting corrosion resistance like new!

Frequently asked questions

- How to improve the wind resistance performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed description and implementation plan of aluminum veneer customization process flow

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 19:45:57

- Click:0

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, corrosion resistance, and easy processing, and has been widely used in the field of architectural decoration. The process flow and implementation plan of customized aluminum veneer are also key factors affecting product quality and effectiveness. Below, we will provide a detailed introduction to the customized process flow and implementation plan for aluminum veneer.

1、 Process description

1. Raw material preparation

The main raw material for aluminum veneer is aluminum coil, which requires strict screening and testing to ensure the quality and stability of the raw materials. At the same time, surface treatment of raw materials is required, including anodizing, electrophoretic coating, powder coating, etc.

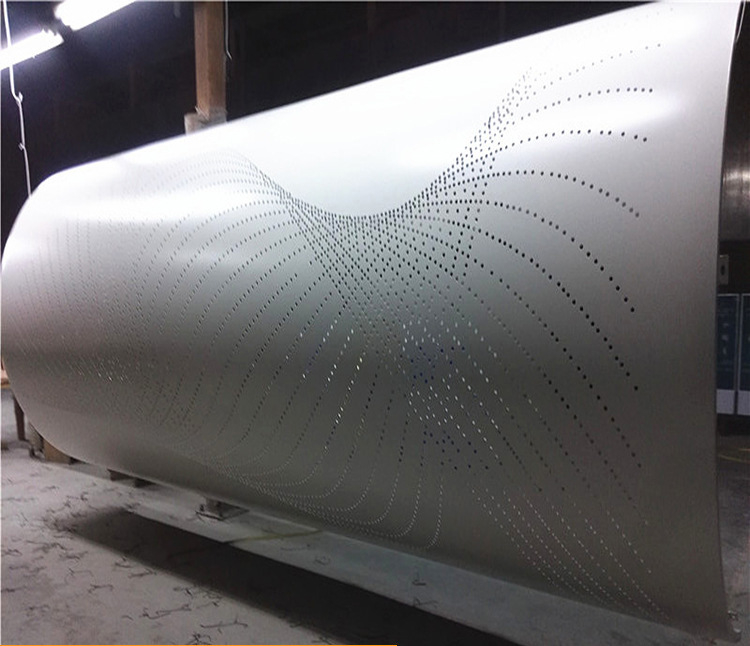

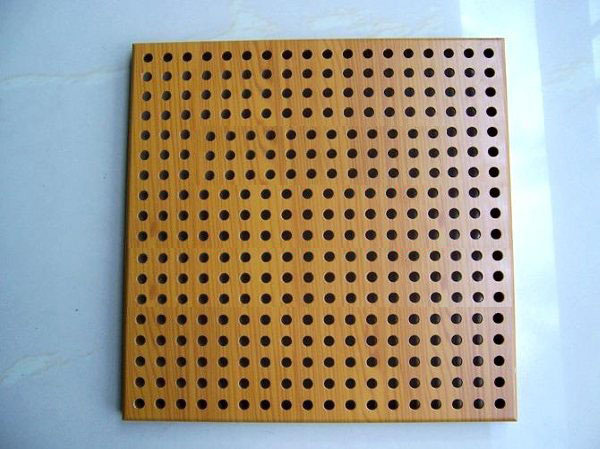

2. Design and production

After completing the preparation of raw materials, it is necessary to design and manufacture aluminum veneer. During the design process, it is necessary to consider factors such as the size, shape, and color of the aluminum veneer, and customize the design according to customer needs. Professional equipment and technology are required during the production process to ensure the quality and accuracy of the aluminum veneer.

3. Welding installation

The welding and installation of aluminum veneer is one of the most critical links in the entire process flow. Attention should be paid to welding quality and safety issues during the welding process to avoid quality problems or safety accidents. At the same time, it is necessary to consider the fixing method and supporting structure of the aluminum veneer to ensure its stability and safety.

4. Surface treatment

The surface treatment of aluminum veneer is one of the last steps in the entire process. Surface treatment can improve the aesthetics and anti-corrosion performance of aluminum veneer. Common surface treatment methods include anodizing, electrophoretic coating, powder coating, etc.

2、 Implementation methods and measures

1. Strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance the competitiveness and profitability of enterprises.

2. Establish a comprehensive quality management system to monitor and manage the entire production process, in order to improve product stability and reliability.

3. Strengthen personnel training and management, improve employees' technical level and work quality, to ensure the smooth progress of the production process.

4. Strengthen cooperation and communication with suppliers, establish long-term stable cooperative relationships to ensure the quality of raw materials and the stability of supply.

5. Strengthen communication and interaction with customers, understand their needs and expectations, and provide more comprehensive and objective selection criteria and service support.

3、 Implementation suggestions

1. Strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance the competitiveness and profitability of enterprises.

2. Establish a comprehensive quality management system to monitor and manage the entire production process, in order to improve product stability and reliability.

3. Strengthen personnel training and management, improve employees' technical level and work quality, to ensure the smooth progress of the production process.

4. Strengthen cooperation and communication with suppliers, establish long-term stable cooperative relationships to ensure the quality of raw materials and the stability of supply.

5. Strengthen communication and interaction with customers, understand their needs and expectations, and provide more comprehensive and objective selection criteria and service support.

4、 Conclusion and Prospect

Through the detailed description and implementation plan of the above aluminum veneer customization process, it can be seen that it is crucial for the successful implementation of aluminum veneer customization projects. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to product quality and service level to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen comparative research with other materials to provide consumers with more comprehensive and objective selection criteria. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ