Industry information

Company News

- Aluminum veneer ceiling, the fashionable "top" choice for modern home furnishings!

- Ceiling aluminum veneer, the secret weapon of spatial aesthetics!

- Aluminum veneer customization, creating a new trend of personalized space

- Ceiling aluminum veneer: the new darling of modern home decoration

- Aluminum veneer: the "light luxury" choice for modern architecture

Industry dynamics

- Aluminum veneer: a fashionable choice in modern architecture

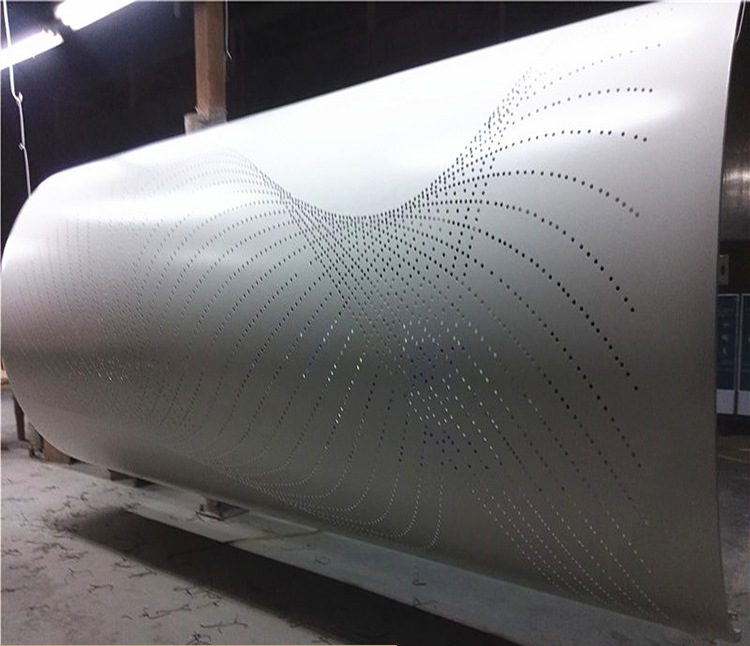

- Application areas of 2.5mm carved aluminum veneer

- Ceiling aluminum veneer, creating a modern and minimalist style home

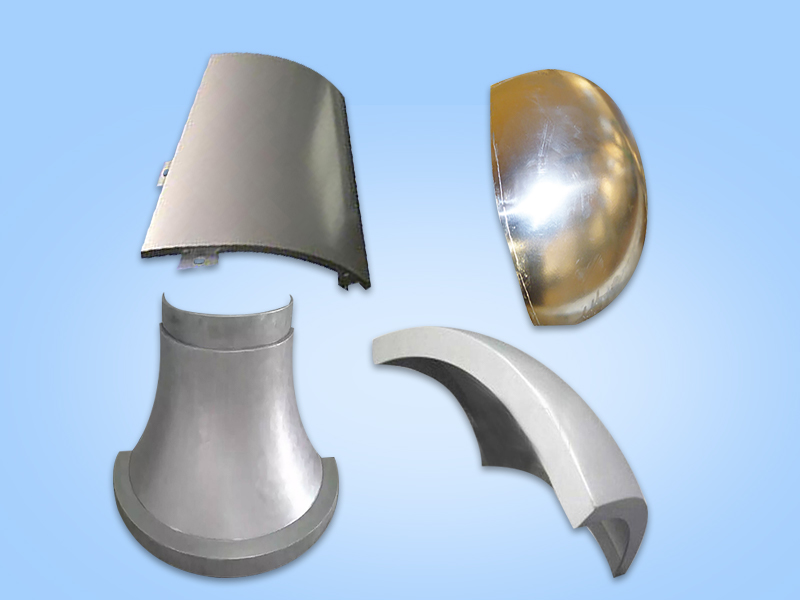

- Customized choice: Arc punched aluminum veneer to meet personalized building needs

- Aluminum veneer ceiling, creating a modern and minimalist beauty

Frequently asked questions

- How to choose to purchase high-quality aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to extend the service life of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality standards and testing methods for aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 at 02:24:00

- Click:0

Aluminum veneerAs a commonly used building material, its quality standards and testing methods are also very important. Only aluminum veneers that meet national and industry standards can ensure their quality and safety. The following will provide a detailed introduction to the quality standards and testing methods for aluminum veneer.

1、 Quality standards

1. National standards

The quality standards for aluminum veneer mainly refer to the national standard "Aluminum Alloy Sheet for Building Decoration" (GB/T 38470-2020). This standard specifies the classification, requirements, test methods, inspection rules and markings, packaging, transportation and storage of aluminum veneer, and is an important basis for the production and use of aluminum veneer.

2. Industry standards

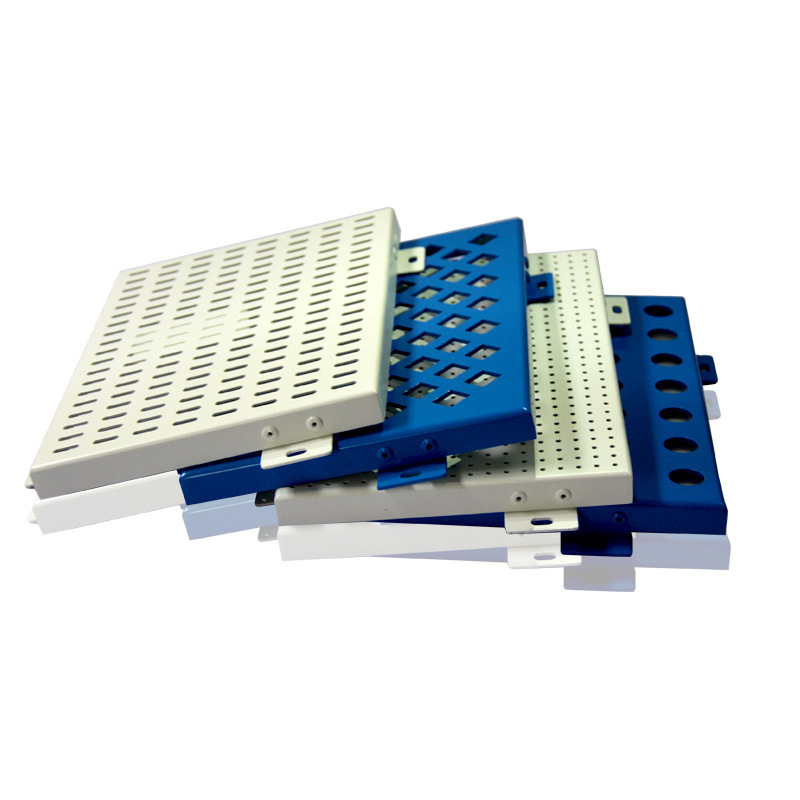

In addition to national standards, the production and use of aluminum veneer also need to follow some industry standards, such as "Aluminum Alloy Sheet for Building Curtain Walls" (JC/T 223-2006), "Aluminum Alloy Profile for Building Curtain Walls" (JC/T 879-2012), etc. These standards provide detailed regulations on the dimensions, thickness, surface treatment, and other aspects of aluminum veneer.

2、 Testing method

1. Appearance inspection

Appearance inspection is one of the important links in the quality inspection of aluminum veneer. The appearance inspection mainly includes whether the surface of the aluminum veneer is flat, without obvious scratches, color difference, etc. Usually, visual inspection or microscopic examination is used for detection.

2. Physical performance testing

The physical properties of aluminum veneer include strength, hardness, density, etc. These properties have a significant impact on the safety and service life of aluminum veneer. Usually, methods such as tensile testing, bending testing, and hardness testing are used for detection.

3. Chemical composition testing

The chemical composition of aluminum veneer also has a significant impact on its performance and safety. Chemical composition detection is usually carried out using methods such as spectroscopic analysis and inductively coupled plasma mass spectrometry.

4. Corrosion resistance testing

Aluminum veneer is susceptible to factors such as oxidation and corrosion during use, therefore corrosion resistance testing is necessary. Usually, methods such as salt spray test and acid gas erosion test are used for detection.

The quality standards and testing methods for aluminum veneer are important means to ensure its quality and safety. When choosing aluminum veneer, customers should choose products that meet national and industry standards; After purchase, strict quality testing should also be conducted to ensure the quality and safety of aluminum veneer.

Customer service QQ

Customer service QQ