Industry information

Company News

- Fluorocarbon aluminum veneer: an innovative element in architectural aesthetics

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer ceiling, creating a new chapter in modern spatial aesthetics

- Aluminum veneer exterior wall, building a fashionable protective shield for the home

- Ceiling aluminum veneer, creating a new trend of modern home furnishings

Industry dynamics

- Exploration into the Market Prospects of Aluminum Veneer

- Aluminum veneer customization, creating a new trend of personalized space!

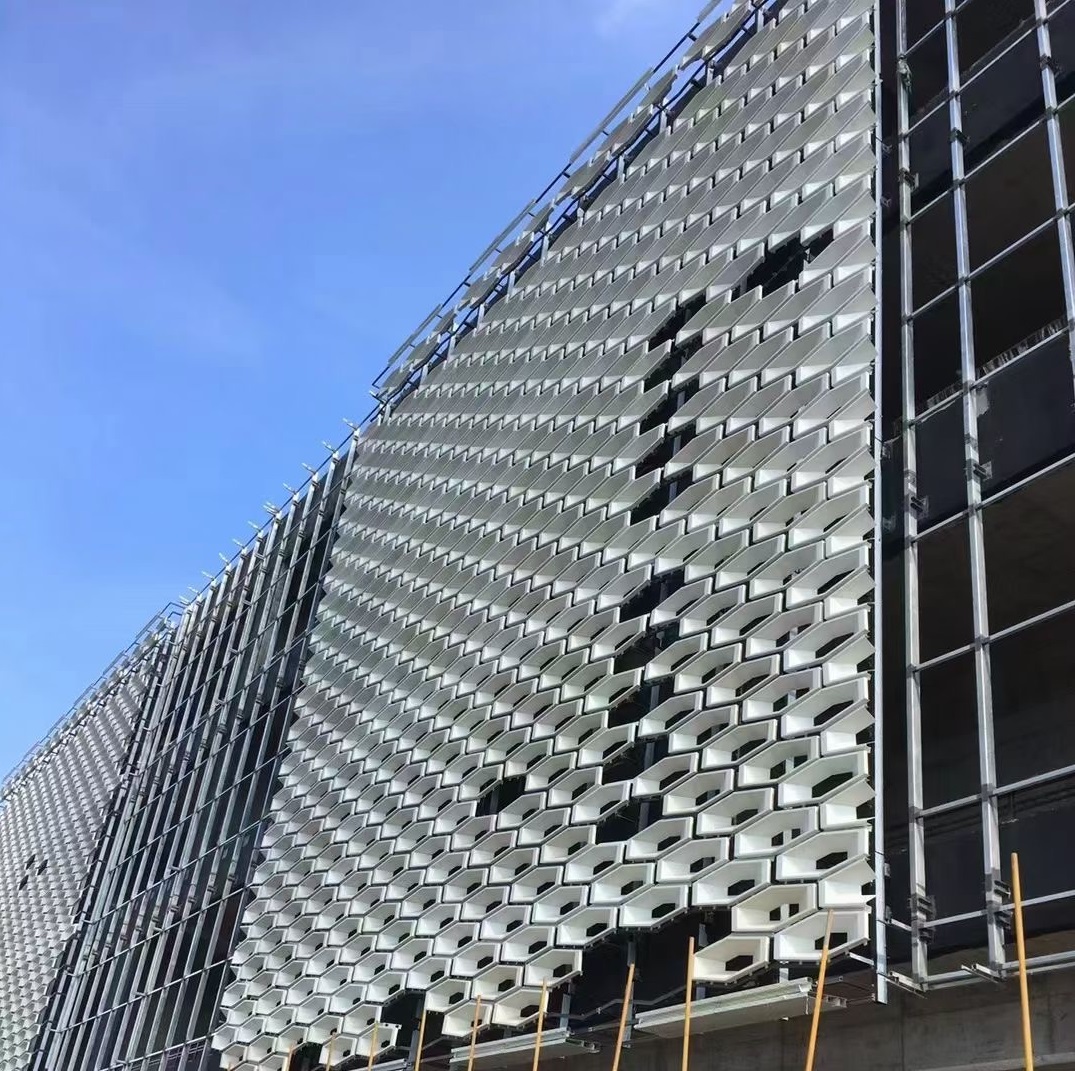

- Can aluminum veneer be used for building shading design?

- Analysis of the practical application effect of perforated hollow aluminum veneer in indoor and outdoor decoration design

- Aluminum veneer customization, creating a new proposition for personalized space

Frequently asked questions

- What is aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the surface treatment technology for fluorocarbon aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-08 08:34:59

- Click:0

FluorocarbonAluminum veneerThe surface treatment technology has a significant impact on its aesthetics and anti-corrosion performance. The surface treatment technology of fluorocarbon aluminum veneer will be introduced in detail below.

1. Anodizing treatment

Anodizing treatment is a commonly used surface treatment technique for fluorocarbon aluminum veneer, which mainly increases the hardness and wear resistance of fluorocarbon coatings, while also improving the corrosion resistance and oxidation resistance of fluorocarbon coatings. During the anodizing process, fluorocarbon aluminum veneer is placed in an electrolyte solution for electrolytic reaction, forming a layer of oxide film. This oxide film has high hardness and wear resistance, which can effectively protect fluorocarbon coatings.

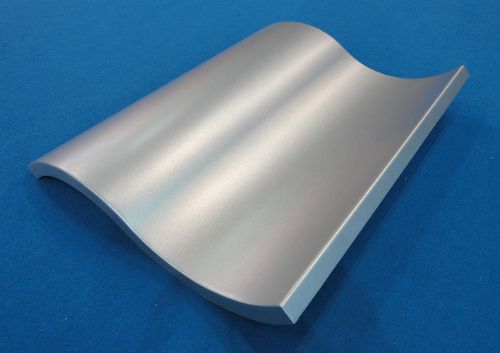

1. Spray treatment

Spray coating is a commonly used surface treatment technique for fluorocarbon aluminum veneer, which mainly increases the color and glossiness of fluorocarbon coatings, while also improving the corrosion resistance and oxidation resistance of fluorocarbon coatings. During the spraying process, fluorocarbon aluminum veneer will be coated with a layer of paint and then cured by high-temperature baking. This coating has good adhesion and durability, which can effectively protect fluorocarbon coatings.

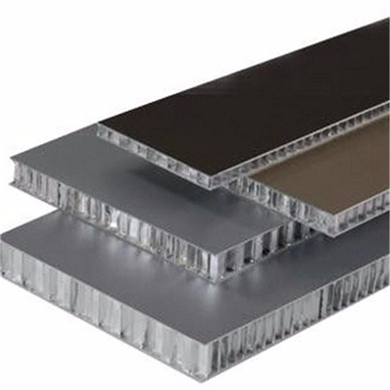

1. Roll pressing treatment

Roll pressing treatment is a commonly used surface treatment technique for fluorocarbon aluminum veneer, which mainly increases the flatness and glossiness of fluorocarbon coatings, while also improving the corrosion resistance and oxidation resistance of fluorocarbon coatings. During the rolling process, fluorocarbon aluminum veneer undergoes multiple rolling processes to form a smooth and even surface. This surface has good decorative effect and mechanical properties, which can effectively protect fluorocarbon coatings.

The surface treatment technology of fluorocarbon aluminum veneer includes multiple steps such as anodizing, spraying, and rolling treatment. These links require strict control of quality and technical requirements to ensure the stability of product quality and performance. In practical applications, consumers should choose products produced by legitimate manufacturers and follow the instructions and maintenance recommendations provided by the manufacturers to ensure the service life and aesthetics of fluorocarbon aluminum veneer.

Customer service QQ

Customer service QQ