Industry information

Company News

- The secret behind aluminum veneer: the new favorite of light luxury lifestyle

- Fluorocarbon aluminum veneer: a new favorite in the construction industry, with both appearance and strength

- Aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space!

- Ceiling aluminum veneer: the new darling of modern architectural aesthetics

Industry dynamics

- Ceiling aluminum veneer: the new darling of fashionable spaces?

- Customized choice: Arc punched aluminum veneer to meet personalized building needs

- The development trend of aluminum veneer in the field of architectural decoration

- Aluminum veneer, the "silver elf" in modern architecture

- Aluminum veneer for exterior walls: a fashionable choice in modern architecture?

Frequently asked questions

- How to improve the wind resistance performance of aluminum veneer?

- How to choose high-quality aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to extend the service life of aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Selection and production process of environmentally friendly materials for carved aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-09 20:43:48

- Click:0

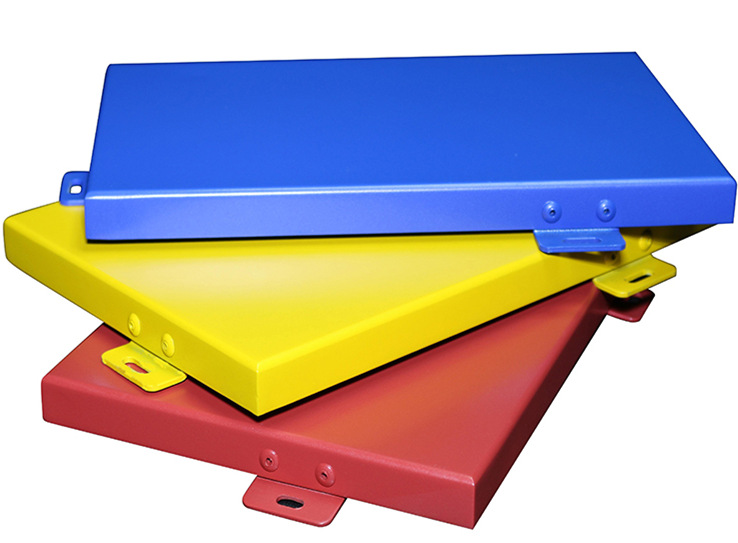

CarvingAluminum veneerAs a new type of building material, the selection and production process of environmentally friendly materials are also very important. Below, we will provide a detailed introduction to the selection and production process of environmentally friendly materials for carved aluminum veneer.

1、 Selection of environmentally friendly materials

1. Raw material selection

The raw material of carved aluminum veneer is mainly aluminum alloy sheet, and the main components of aluminum alloy sheet are metal elements such as aluminum and magnesium. These metal elements are very environmentally friendly materials and will not cause pollution to the environment.

2. Surface coating

In order to improve the decorative performance and durability of carved aluminum veneer, a layer of fluorocarbon paint or other environmentally friendly coatings is usually applied to the surface of the aluminum sheet. These coatings not only protect aluminum sheets from oxidation, corrosion, and other effects, but also increase their aesthetics and service life.

3. Processing technology

The processing technology of carved aluminum veneer mainly includes cutting, stamping, bending, welding and other processes. These processing techniques require the use of advanced equipment and technology to ensure product quality and production efficiency while reducing environmental impact.

2、 Production process

1. Cutting process

The cutting process of carved aluminum veneer is mainly carried out using CNC cutting machines. Numerical control cutting machines can accurately control cutting dimensions and angles, avoiding errors and waste in traditional manual cutting. Numerical control cutting machines can also achieve automated production, improving production efficiency and product quality.

2. Stamping process

The stamping process of carved aluminum veneer mainly uses hydraulic punching machines. Hydraulic punching machines can accurately control the punching force and angle, avoiding errors and waste in traditional manual punching. Hydraulic punching machines can also achieve automated production, improving production efficiency and product quality.

3. Bending process

The bending process of carved aluminum veneer is mainly carried out using CNC bending machines. CNC bending machines can accurately control the bending size and angle, avoiding errors and waste in traditional manual bending. CNC bending machines can also achieve automated production, improving production efficiency and product quality.

4. Welding process

The welding process of carved aluminum veneer is mainly carried out by automatic welding machines. Automatic welding machines can accurately control the welding position and force, avoiding errors and waste in traditional manual welding. Automatic welding machines can also achieve automated production, improving production efficiency and product quality.

3、 Conclusion

By introducing the selection of environmentally friendly materials and production processes for carved aluminum veneer, the following conclusion can be drawn: as a new type of building material, carved aluminum veneer has excellent environmentally friendly material selection and production processes, which meet the requirements of modern society for environmental protection. In the future development, carved aluminum veneer will continue to leverage its advantages and make greater contributions to the sustainable development of the construction industry.

Customer service QQ

Customer service QQ