Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating an exclusive personalized space

- Aluminum veneer ceiling, the fashionable "top" choice for modern home furnishings!

- Aluminum veneer ceiling: the beauty of modern simplicity

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry

Industry dynamics

- Application cases of aluminum veneer in the field of architectural decoration

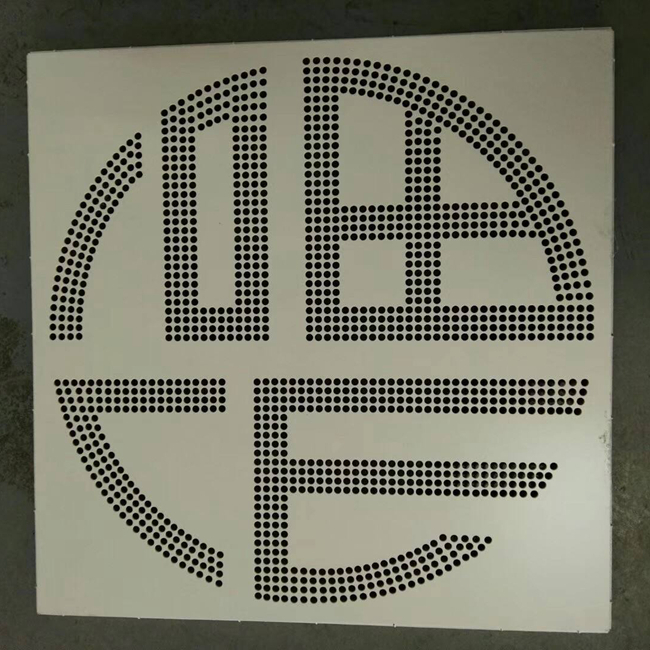

- Innovative design showcases exquisite craftsmanship - the charm of hollow aluminum veneer at the door head

- Unveiling the ceiling aluminum veneer: the new darling of modern decoration!

- Ceiling aluminum veneer: the new favorite of modern home decoration

- Ceiling aluminum veneer: a fashionable choice for modern home furnishings

Frequently asked questions

- How to choose high-quality aluminum veneer?

- How to store and transport aluminum veneer correctly?

- What is aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the ventilation performance of perforated aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 12:47:28

- Click:0

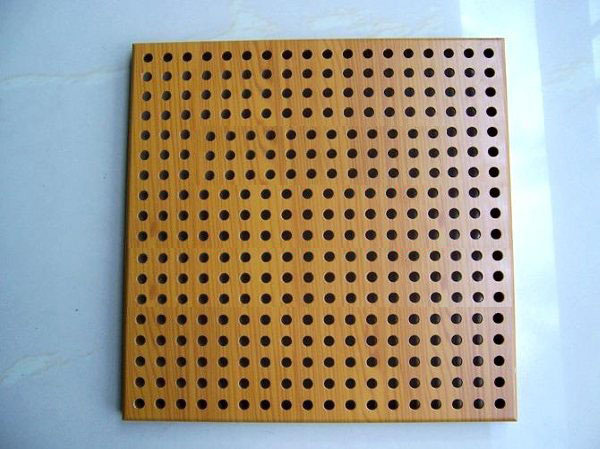

punchingAluminum veneerAs a material widely used in fields such as architectural decoration, billboards, curtain walls, etc., its ventilation performance is also an important aspect. The ventilation performance of perforated aluminum veneer will be introduced from the following aspects.

1. Definition of ventilation performance

Ventilation performance refers to the ability of materials to circulate and exchange air, that is, to maintain fresh, dry, and comfortable indoor air. For perforated aluminum veneer, its ventilation performance is mainly manifested in its ability for natural ventilation and mechanical ventilation.

1. Factors affecting the ventilation performance of perforated aluminum veneer

The ventilation performance of perforated aluminum veneer is influenced by various factors, including material composition, surface treatment method, coating thickness, etc. The material composition is one of the most important factors determining the ventilation performance of perforated aluminum veneer. Generally speaking, aluminum alloy materials have better ventilation performance. The surface treatment method and coating thickness can also affect the ventilation performance of punched aluminum veneer. For example, anodizing can improve the surface hardness and wear resistance of punched aluminum veneer, thereby reducing air flow resistance; Electrophoretic coating and fluorocarbon spraying can form a uniform and dense coating, thereby improving its ventilation performance.

1. Methods to improve the ventilation performance of punched aluminum veneer

In order to improve the ventilation performance of punched aluminum veneer, some measures can be taken. The ventilation performance can be improved by optimizing the material composition. For example, increasing the content of alloying elements can improve the strength and hardness of aluminum alloy materials, thereby enhancing their durability. Different surface treatment methods can be used to enhance the corrosion resistance and oxidation resistance of punched aluminum veneer. A protective coating can be applied to punched aluminum veneer to reduce its contact with the external environment and extend its service life.

1. Ventilation requirements in application scenarios

Due to the different application scenarios of punched aluminum veneer, the requirements for its ventilation performance also vary. For example, perforated aluminum veneer used in high-rise buildings needs to have high ventilation performance to ensure indoor air circulation and freshness; The perforated aluminum veneer used in outdoor billboards needs to have good weather resistance and UV resistance to ensure its long-term effectiveness remains unchanged.

1. Comparison of common ventilation materials

In addition to punching aluminum veneer itself, there are other common ventilation materials available, such as glass, polyurethane foam, rock wool, etc. These materials have their own advantages and disadvantages in terms of ventilation performance, and the specific selection should be based on actual needs. For example, glass has good transparency and aesthetics, but poor insulation performance; Polyurethane foam has good thermal insulation performance and cost efficiency, but its weight is large; Rock wool has good water resistance and weather resistance, but it is difficult to construct.

The ventilation performance of punched aluminum veneer is one of the important guarantees for its application effect and user experience. By optimizing material composition, surface treatment methods, and coating thickness, the ventilation performance of punched aluminum veneer can be improved to meet the needs of different occasions. When selecting ventilation materials, comprehensive consideration should be given to actual needs, and the most suitable materials should be chosen to achieve the best ventilation effect.

Customer service QQ

Customer service QQ