Industry information

Company News

- Aluminum veneer: the new favorite in the construction industry, revealing its charm!

- Ceiling aluminum veneer: the new darling for creating fashionable spaces

- Ceiling aluminum veneer, the new darling of fashionable home decor!

- Ceiling aluminum veneer: the new darling of modern architecture, revealing its unique charm

- Aluminum veneer customization, creating a unique spatial aesthetic

Industry dynamics

- Aluminum veneer curtain wall creates a new modern urban landscape

- Production and processing process of fluorocarbon aluminum veneer

- Technology driven hyperbolic aluminum veneer design

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the fashion darling of the construction industry

Frequently asked questions

- How to extend the service life of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to test the anti-corrosion performance of punched aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 27, 2025 21:37:32

- Click:0

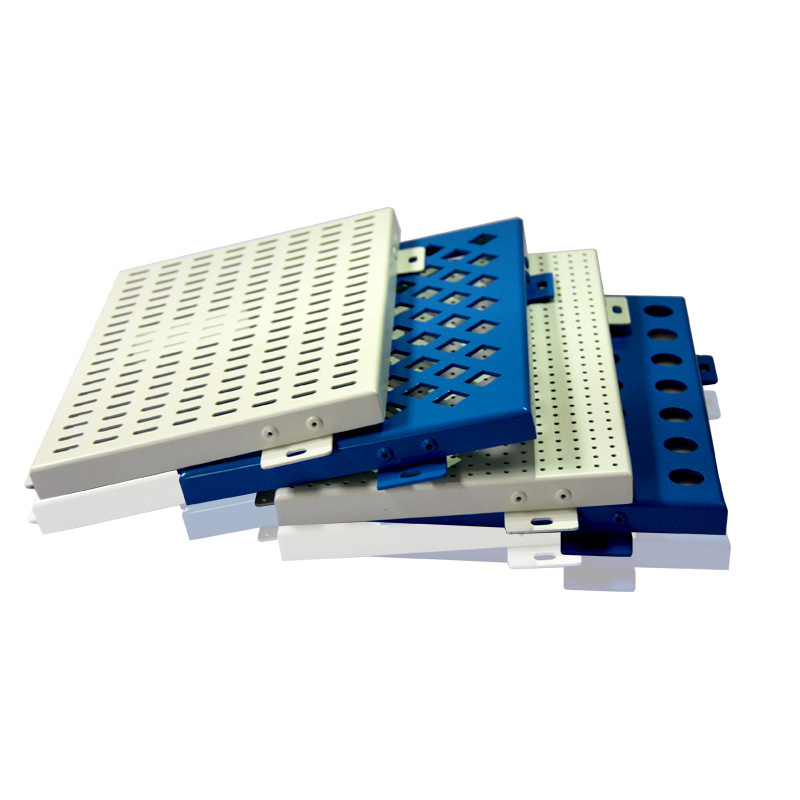

punchingAluminum veneerAs a material widely used in fields such as architectural decoration, billboards, curtain walls, etc., its anti-corrosion performance is also an important aspect. In order to ensure that the anti-corrosion performance of punched aluminum veneer meets the requirements, it is necessary to conduct testing and inspection. The following will introduce how to test the anti-corrosion performance of punched aluminum veneer from the following aspects.

1. Appearance inspection

Firstly, it is necessary to inspect the appearance of the punched aluminum veneer, including whether there are obvious scratches, unevenness, and bumps on the surface. These issues may affect its anti-corrosion performance, so they need to be addressed in a timely manner.

1. Chemical composition analysis

Secondly, the chemical composition of punched aluminum veneer can be analyzed to determine whether it meets relevant national or industry quality standards and requirements. Generally speaking, aluminum alloy materials have high corrosion resistance, but the corrosion resistance of different types of aluminum alloy materials may also vary. When choosing perforated aluminum veneer, attention should be paid to its chemical composition.

1. Electrochemical testing

Electrochemical testing is a commonly used testing method that can determine parameters such as polarization curve and potential current relationship of punched aluminum veneer, in order to determine its corrosion resistance performance. Electrochemical testing generally includes neutral salt spray test, acidic salt spray test, and alkaline salt spray test. These experiments can simulate different environmental conditions, such as oceans, industrial areas, etc., to comprehensively evaluate the corrosion resistance of punched aluminum veneer.

1. Hydrostatic test

Water pressure test is a relatively strict testing method that can test the corrosion resistance of punched aluminum veneer under different water pressures. This testing method is suitable for fields such as large buildings and high-rise buildings, as there may be higher water pressure and greater water flow impact in these areas.

1. How to improve the anti-corrosion performance of punched aluminum veneer

In order to improve the anti-corrosion performance of punched aluminum veneer, the following measures can be taken:

(1) Strengthen raw material quality management: Strengthen the screening and testing of raw materials to ensure that they meet relevant national or industry quality indicators and standards, thereby ensuring the anti-corrosion performance of punched aluminum veneer.

(2) Optimizing surface treatment process: By optimizing the surface treatment process, the corrosion resistance and wear resistance of punched aluminum veneer can be improved, thereby enhancing its anti-corrosion performance.

(3) Strengthening structural design management: By enhancing the management and control of structural design, the transparency and ventilation characteristics of perforated aluminum veneer can be increased, thereby further improving its anti-corrosion performance.

By strengthening appearance inspection, chemical composition analysis, electrochemical testing, hydrostatic testing and other methods, the anti-corrosion performance of punched aluminum veneer can be effectively tested and inspected, thus meeting the needs of different occasions. By strengthening the quality management of raw materials, optimizing surface treatment processes, and enhancing structural design management, the anti-corrosion performance of punched aluminum veneer can be further improved.

Customer service QQ

Customer service QQ