Industry information

Company News

- Aluminum veneer ceiling, a ceiling with home aesthetics

- Aluminum veneer ceiling: a lightweight choice, a new trend in home decor

- Aluminum exterior wall, perfect fusion of fashion and durability

- Ceiling aluminum veneer: the new darling of modern architecture, revealing its unique charm

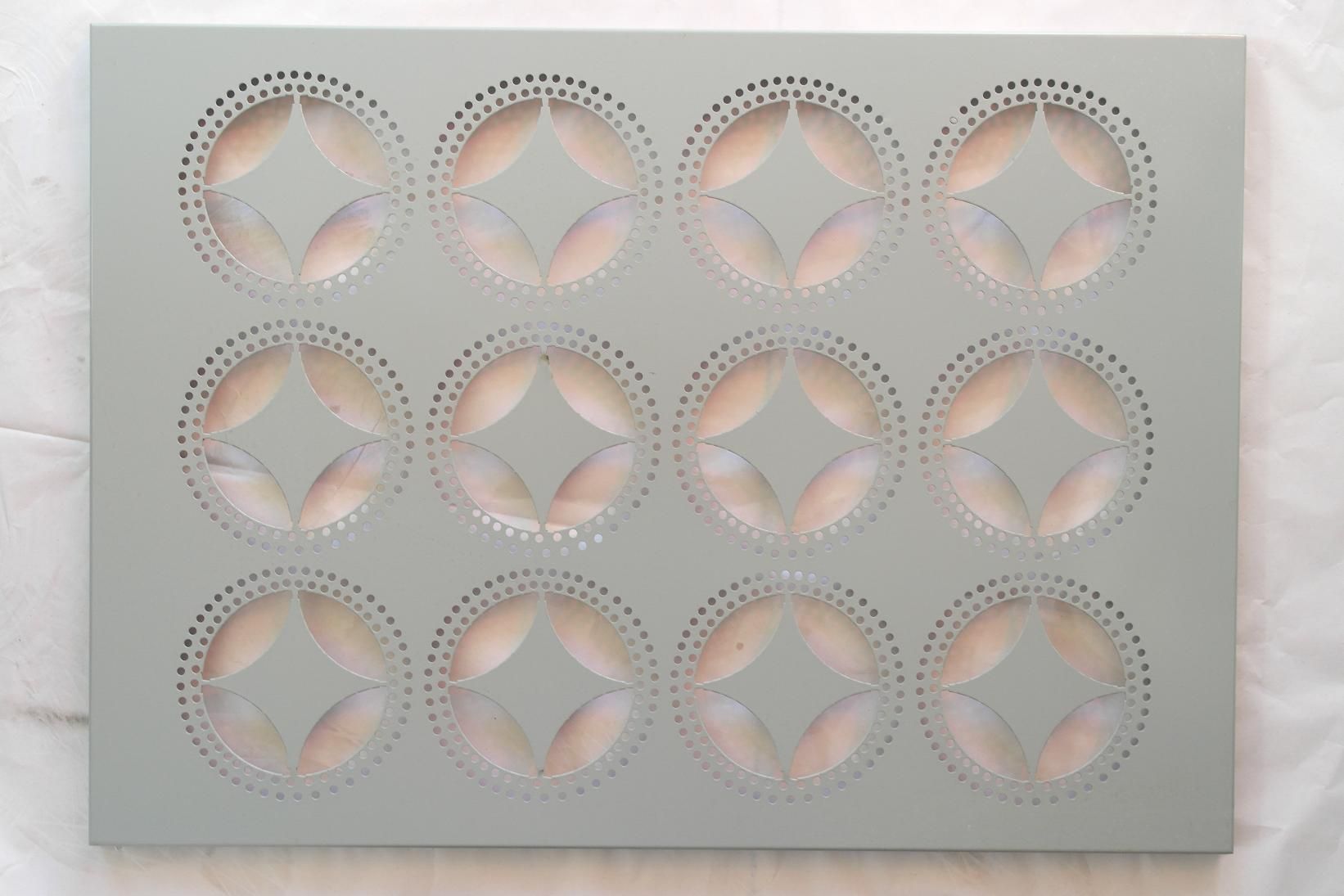

- Aluminum veneer customization, creating personalized space art

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the new darling of future architecture?

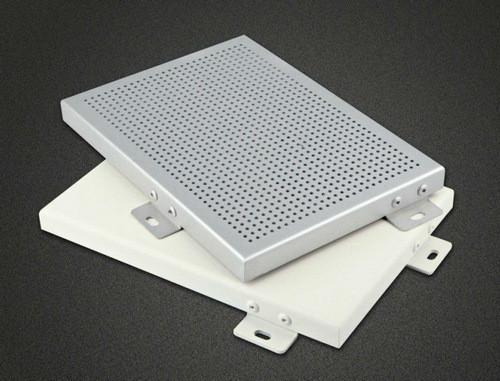

- Can't you think of it? Punched aluminum veneer can be used like this!

- Impact resistance of aluminum veneer

- Color matching and design inspiration for aluminum veneer

Frequently asked questions

- How to store and transport aluminum veneer correctly?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to choose the most suitable aluminum veneer material?

- How to extend the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

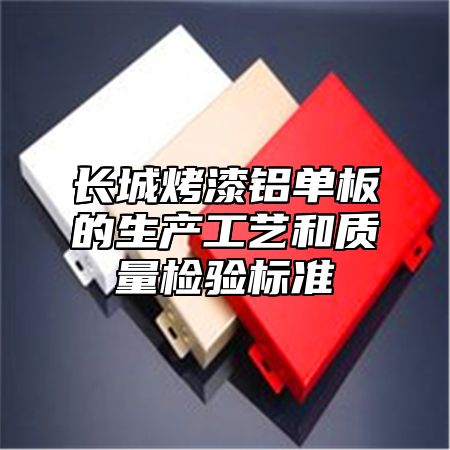

Production process and quality inspection standards for Great Wall baked paint aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-21 20:28:17

- Click:0

Great Wall PaintAluminum veneerIt is a high-end building material, and its production process and quality inspection standards are crucial to ensuring product quality. The following is a detailed introduction to the production process and quality inspection standards of Great Wall baked paint aluminum veneer:

1、 Production process

1. Raw material selection: The main raw material for Great Wall painted aluminum veneer is aluminum alloy, which is required to have high strength and corrosion resistance.

2. Pre processing: Before production, raw materials need to be pre processed, including cutting, drilling, slotting, and other processes, for subsequent processing.

3. Surface treatment: The surface of Great Wall painted aluminum veneer needs to be treated multiple times to achieve the desired effect. Firstly, the raw materials are subjected to anodizing treatment to form a layer of oxide film on their surface, and then subjected to processes such as spraying and baking paint, ultimately resulting in a uniform, smooth, and brightly colored surface.

4. Assembly and installation: After completing surface treatment, assemble and install the Great Wall painted aluminum veneer according to the design requirements to ensure that its overall performance meets the requirements.

2、 Quality Inspection Standards

1. Appearance inspection: Appearance inspection is one of the most basic quality inspection standards. The inspection includes checking whether the surface is flat, free of scratches, and whether the color difference is consistent.

2. Dimensional inspection: Dimensional inspection is an important means of ensuring product accuracy. The inspection includes checking whether the dimensions such as length, width, and thickness meet the design requirements.

3. Strength testing: Strength testing is one of the key indicators for inspecting product quality. The testing methods include tensile testing, bending testing, etc.

4. Corrosion resistance test: Corrosion resistance test is one of the important indicators to measure the service life of products. The testing methods include salt spray test, acid gas test, etc.

The production process and quality inspection standards of Great Wall painted aluminum veneer are crucial for ensuring product quality. Only by strictly following standards in production and inspection can we ensure that product quality meets customer requirements and win market recognition.

Customer service QQ

Customer service QQ