Industry information

Company News

- Ceiling aluminum veneer: dual guarantee of quality and aesthetics

- Aluminum veneer for exterior walls: creating a new style of modern architecture

- Ceiling aluminum veneer, creating a new choice for fashionable spaces!

- Aluminum veneer ceiling: the new darling of fashionable space

- New home ceiling aluminum veneer, perfect combination of simplicity and high-end

Industry dynamics

- Ceiling aluminum veneer: the new darling of modern home decoration?

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- The unique charm of ceiling aluminum veneer: the perfect combination of lightness and sturdiness

- Aluminum veneer customization, creating a new trend of personalized space!

- Ceiling aluminum veneer, the "invisible" fashion of modern home furnishings

Frequently asked questions

- How to choose the most suitable aluminum veneer material?

- How to extend the service life of aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to improve the wind resistance performance of aluminum veneer?

- What is aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and technical analysis of wood grain aluminum square tube for curtain wall

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-20 12:34:57

- Click:0

Curtain wall wood grain aluminum square tube is a common building decoration material, and its production process and technology are also very important. Below, we will provide a detailed introduction to the production process and technology of wood grain aluminum square tubes for curtain walls.

1、 Material preparation

The production of wood grain aluminum square tubes for curtain walls requires the use of aluminum alloy materials and surface treatment materials. In terms of material preparation, it is necessary to choose high-quality aluminum alloy materials and ensure that they meet relevant quality standards. It is also necessary to prepare surface treatment materials to ensure the surface effect and corrosion resistance of the curtain wall wood grain aluminum square tube.

2、 Cutting and processing

In terms of cutting and processing, CNC machine tools are generally used to ensure cutting dimensional accuracy and surface smoothness. During the processing, attention should be paid to avoiding defects such as scratches and burrs to ensure product quality.

3、 Welding processing

In terms of welding processing, it is necessary to use professional welding equipment for welding to ensure the quality and strength of the weld seam. During the welding process, it is necessary to pay attention to controlling the welding temperature and time to avoid welding defects and deformations.

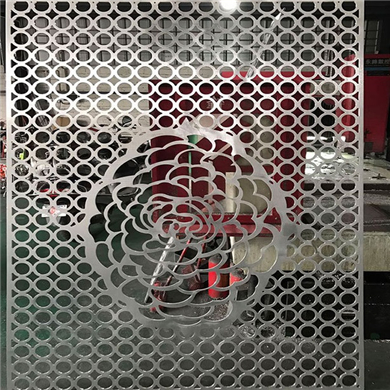

4、 Surface treatment

In terms of surface treatment, it is necessary to anodize or spray treat the wood grain aluminum square tube of the curtain wall to improve its surface corrosion resistance and aesthetics. During the processing, it is necessary to pay attention to controlling the processing time and temperature to avoid problems such as color difference and bubbles.

5、 Inspection and testing

After the production is completed, it is necessary to inspect and test the wood grain aluminum square tube of the curtain wall to ensure that its quality meets the relevant standard requirements. During the inspection and testing process, it is necessary to inspect and test the dimensions, strength, surface effect, and other aspects of the product.

6、 Summary

The production process and technology of wood grain aluminum square tube for curtain wall are very important. Through strict material preparation, precise cutting and processing, professional welding, high-quality surface treatment, and rigorous inspection and testing, curtain wall wood grain aluminum square tube products that meet design requirements and quality standards can be produced. At the same time, it can also improve the aesthetics, energy efficiency, environmental protection, safety, and intelligence level of buildings, creating a better living and working environment for people.

Customer service QQ

Customer service QQ