Industry information

Company News

- Performance and Application of Aluminum Veneer in Thermal Insulation

- New home ceiling aluminum veneer, perfect combination of simplicity and high-end

- Aluminum veneer ceiling: the new darling of modern home decoration

- Aluminum veneer is not just a building material, but also a perfect fusion of art and innovation!

- Ceiling aluminum veneer, new fashion in home decoration

Industry dynamics

- Ceiling aluminum veneer: a minimalist yet sophisticated design aesthetic

- Ceiling aluminum veneer, creating a new trend of modern home decor

- Aluminum veneer ceiling, creating a new trend of fashionable space

- How to choose suitable aluminum square curtain wall materials for exterior walls

- Application of carved aluminum veneer in architectural decoration

Frequently asked questions

- How to improve the corrosion resistance of aluminum veneer?

- How to store and transport aluminum veneer correctly?

- How to choose to purchase high-quality aluminum veneer?

- What is aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality assurance measures for aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-18 20:47:42

- Click:0

Aluminum veneerAs a new type of building material, it has the advantages of light weight, high strength, and corrosion resistance, and is widely used in fields such as building curtain walls and interior decoration. In order to ensure the quality of aluminum veneer, enterprises need to take a series of measures. Below, we will provide a detailed introduction to the quality assurance measures for aluminum veneer.

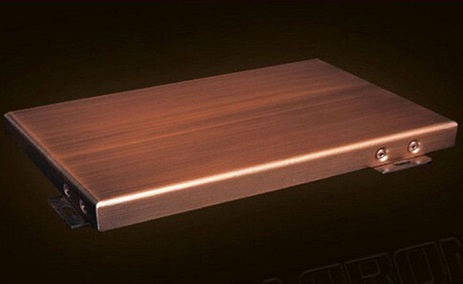

1、 Raw material procurement

Raw materials are one of the key factors affecting the quality of aluminum veneer. Enterprises need to choose high-quality raw material suppliers and conduct strict audits and testing on them. Enterprises also need to establish a sound raw material procurement management system to ensure that the quality of raw materials meets standard requirements.

2、 Production process control

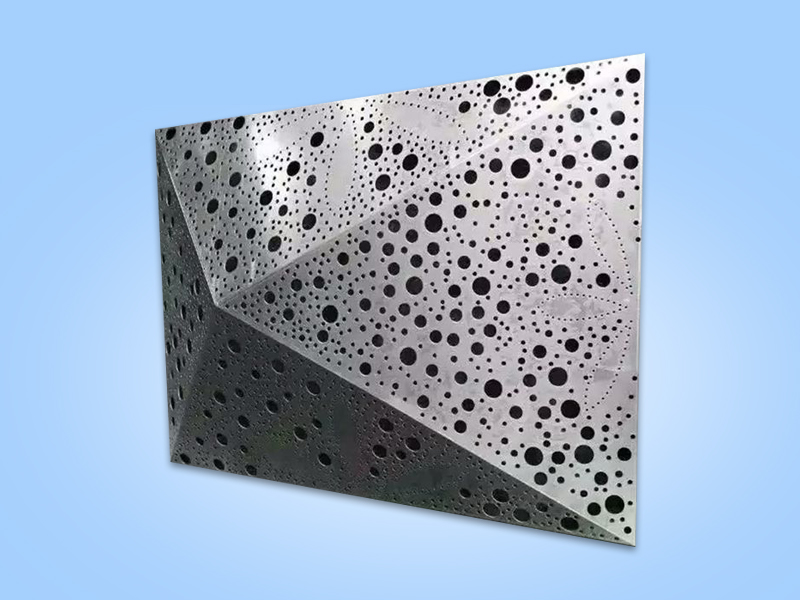

Production process control is an important link in ensuring the quality of aluminum veneer. Enterprises need to establish a sound production process and quality management system, and strictly control and manage every production link. For example, advanced automated production lines and equipment can be used to improve production efficiency and product quality; Strict inspection and testing can be carried out for each process to ensure that the product meets the standard requirements.

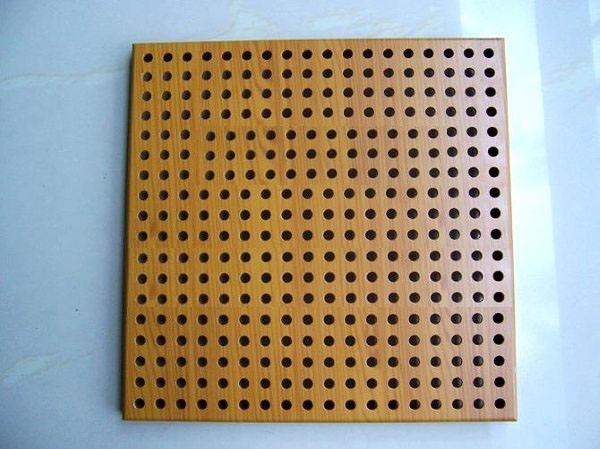

3、 Surface treatment process

Surface treatment process is one of the key factors affecting the appearance and service life of aluminum veneer. Enterprises need to adopt advanced surface treatment processes and technologies to finely polish, spray, anodize, and other treatments on aluminum veneers to improve product aesthetics and durability. Enterprises also need to conduct strict quality control and testing of surface treatment processes to ensure that products meet standard requirements.

4、 Quality Inspection and Certification

Quality inspection and certification are important means to ensure the quality of aluminum veneer. Enterprises need to establish a sound quality inspection system and certification mechanism, and conduct strict inspections and tests on every aspect. Enterprises also need to obtain relevant certifications and qualifications to enhance the market competitiveness and reputation of their products.

5、 After sales service guarantee

After sales service guarantee is one of the manifestations of a company's responsibility to customers. Enterprises need to provide timely and professional after-sales service, actively handle and resolve customer feedback and complaints. Enterprises also need to establish a comprehensive customer profile and service system to provide customers with a more intimate service experience.

6、 Summary

The quality assurance measures for aluminum veneer include multiple aspects such as raw material procurement, production process control, surface treatment technology, quality inspection and certification, and after-sales service guarantee. By implementing these measures, the quality and performance of aluminum veneer can be effectively improved, meeting the needs and expectations of customers.

Customer service QQ

Customer service QQ