Industry information

Company News

- Unveiling the Charm and Value of Exterior Aluminum Veneers

- Aluminum veneer customization: infinite possibilities for personalized space

- Ceiling aluminum veneer: a hidden master in creating fashionable homes

- Ceiling aluminum veneer: a new favorite in decoration, a choice for light luxury

- Aluminum veneer: the "green guardian" of modern architecture

Industry dynamics

- Discussion on the anti-corrosion performance of aluminum veneer

- Aluminum veneer ceiling: a shining pearl in modern architecture

- Ceiling aluminum veneer: a luxurious space separated by a single panel

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer for exterior walls, the finishing touch of architectural aesthetics

Frequently asked questions

- How to choose high-quality aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- How to choose to purchase high-quality aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to extend the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

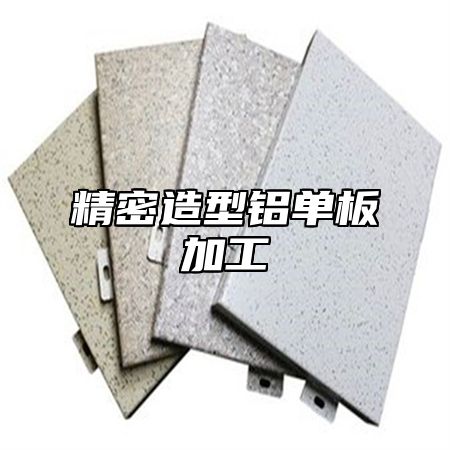

Precision shaped aluminum veneer processing

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 25, 2025 18:45:58

- Click:0

Precision modelingAluminum veneerProcessing is a process of highly precise machining and manufacturing of aluminum veneer using advanced CNC machine tools and processing techniques. This processing can achieve high-precision, high-quality, and high-efficiency production of aluminum veneer, bringing new opportunities and challenges to the aluminum veneer industry. This article will provide a detailed introduction to the characteristics and applications of precision molded aluminum veneer processing.

Precision molded aluminum veneer processing has very high precision and quality. By using CNC machine tools and processing techniques, high-precision machining and manufacturing of aluminum veneer can be achieved, thereby ensuring that the dimensional accuracy, shape accuracy, and surface smoothness parameters of aluminum veneer meet the requirements. Precision molding aluminum veneer processing can also achieve diversified processing and manufacturing of aluminum veneer, such as hollowing, carving, punching and other processes, to meet the needs of different customers.

Precision molded aluminum veneer processing has very high efficiency and flexibility. Due to the use of CNC machine tools and computer control systems, automated production processes can be achieved, greatly improving production efficiency and capacity. Due to the flexible and versatile processing technology, customized production can be carried out according to different needs to meet the requirements of different customers.

The application range of precision shaped aluminum veneer processing is very wide. In the field of architecture, it can be applied to curtain walls, ceilings, doors and windows, and other areas to achieve more beautiful, practical, and durable building appearance and interior decoration effects; In the field of transportation, it can be applied to the manufacturing of vehicles such as cars, airplanes, and ships to achieve lighter, stronger, and more corrosion-resistant vehicle casings; In the field of electronics, it can be applied to the manufacturing of casings for electronic products such as mobile phones and computers to achieve more beautiful, practical, and environmentally friendly design effects.

Precision molding aluminum veneer processing is a very important technological innovation and practice, which can bring more efficient, precise, and flexible production methods to the aluminum veneer industry. With the continuous advancement of technology and the increasing demand for product quality and efficiency, it is believed that precision shaped aluminum veneer processing will be more widely and deeply developed and applied.

Customer service QQ

Customer service QQ