Industry information

Company News

- Ceiling aluminum veneer, a new trend in modern home decor

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating an exclusive personalized space

- 2. Aluminum veneer ceiling, fashionable new clothes for the ceiling! Speaking of our home or office

- Ceiling aluminum veneer: a perfect combination of fashion and practicality

Industry dynamics

- Innovative application of aluminum veneer in urban buildings

- Analysis of the advantages of environmentally friendly material special-shaped carved aluminum veneer

- Aluminum veneer ceiling: the new darling of creating fashionable spaces

- Exploration of the Application of Wave Suspended Aluminum Veneer in Architectural Decoration

- Performance and advantages analysis of twisted 1.5mm aluminum veneer

Frequently asked questions

- How to improve the wind resistance performance of aluminum veneer?

- How to improve the corrosion resistance of aluminum veneer?

- How to choose high-quality aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to extend the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Selection and use of high-quality perforated aluminum veneer for curtain wall materials

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 11, 2025 13:17:55

- Click:0

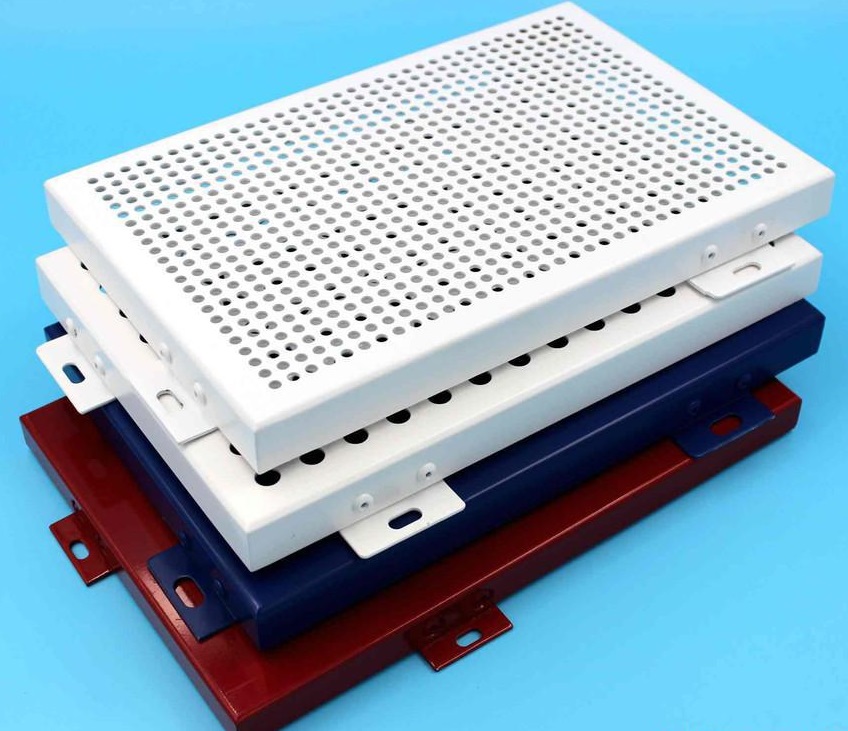

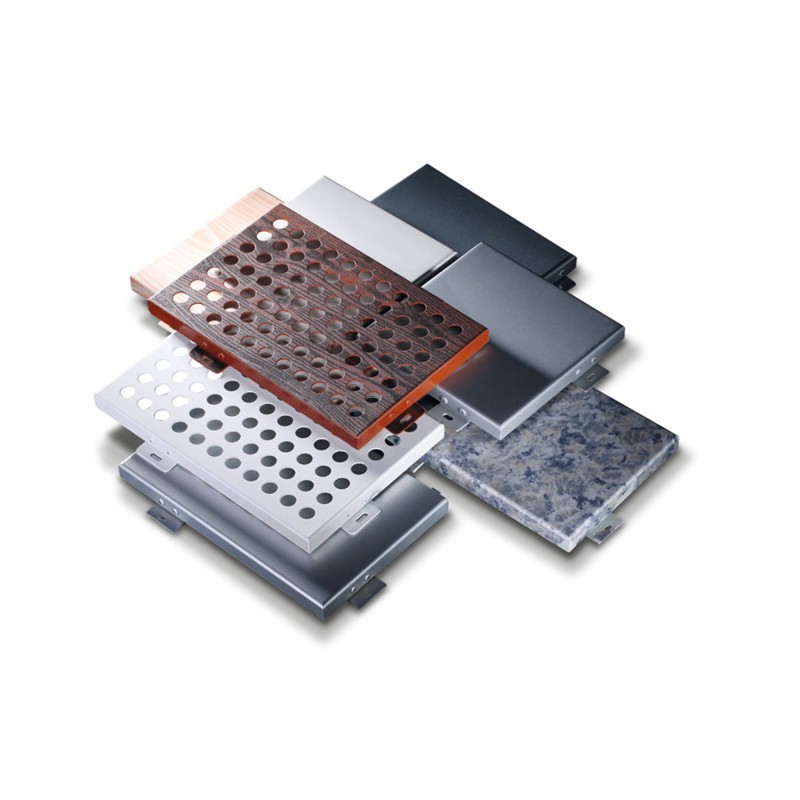

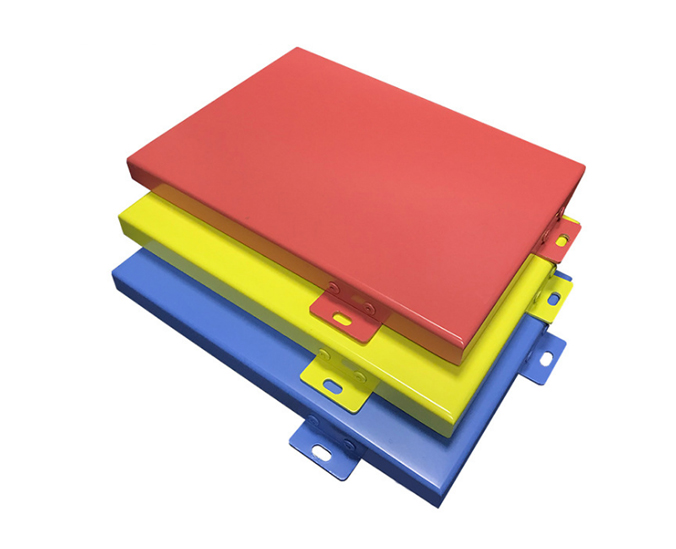

With the continuous development of the construction industry, curtain walls have become an indispensable part of modern architecture. And punching holesAluminum veneerAs a new type of curtain wall material, it has the advantages of light weight, high strength, and corrosion resistance, and is widely used in various buildings. Below, we will provide a detailed introduction to the selection and use of high-quality perforated aluminum veneer for curtain walls.

1、 Choose high-quality materials

1. Aluminum alloy sheet: The main raw material for punched aluminum veneer is aluminum alloy sheet, and high-quality aluminum alloy sheet that meets national standards and quality requirements should be selected to ensure its strength and corrosion resistance.

2. Anodizing film: After anodizing treatment, a dense oxide film can be formed on the surface of punched aluminum veneer. High quality oxide films that meet national standards and quality requirements should be selected to ensure their corrosion resistance and wear resistance.

3. Sealing glue: Sealing glue is required during the assembly and installation process of punched aluminum veneer. Environmentally friendly sealing glue that meets national standards and quality requirements should be selected to ensure its non-toxic, environmentally friendly, and bonding performance.

2、 Usage method

1. Measurement of dimensions: Before installing perforated aluminum veneer, the actual dimensions should be measured to ensure that they match the actual dimensions of the building.

2. Keel installation: Install the keel according to the design requirements and fix it to the structure of the building.

3. Installation of perforated aluminum veneer: Install the perforated aluminum veneer according to the design requirements and fix it with sealant.

4. Inspection and acceptance: After the installation of punched aluminum veneer is completed, inspection and acceptance should be carried out to ensure that it meets the design requirements and national standards.

3、 Precautions

1. Avoid collisions with heavy objects: During the installation process of punched aluminum veneer, collisions and squeezing with heavy objects should be avoided to prevent damage to it.

2. Regular maintenance: During use, punched aluminum veneer should be regularly maintained, including cleaning, anti-corrosion measures, etc., to extend its service life.

4、 Conclusion

It is very important to choose high-quality materials for perforated aluminum panels in curtain walls. Only by selecting materials that meet national standards and quality requirements can their strength and corrosion resistance be guaranteed. During use, attention should also be paid to avoiding collisions with heavy objects and regular maintenance. In the future, with the continuous advancement and innovation of technology, it is believed that the application scope of punched aluminum veneer will be more extensive and in-depth.

Customer service QQ

Customer service QQ