Industry information

Company News

- Aluminum veneer ceiling: the fashionable choice for modern home furnishings

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer for exterior walls: the magnificent coat of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: a new favorite in the construction industry and a guardian of green environmental protection!

Industry dynamics

- Application effect of fluorocarbon coated column aluminum veneer in architectural decoration

- Ceiling aluminum veneer, the unique style of modern architecture

- 2. Customize aluminum veneer to make the home more stylish. 3 Aluminum veneer customization, creating a unique style

- Multiple uses and cross-border cooperation of aluminum veneer

- Reflection characteristics and light utilization of aluminum veneer

Frequently asked questions

- How to choose high-quality aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the wind resistance performance of aluminum veneer?

- How to extend the service life of aluminum veneer?

- What is aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Four surface treatment technologies for aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 22, 2025 21:09:08

- Click:0

Aluminum veneerAs a new type of building material, it has been widely used in the field of architectural decoration. In order to meet different occasions and needs, the surface treatment technology of aluminum veneer is becoming increasingly diversified. Below, we will introduce four common surface treatment techniques for aluminum veneer.

1. Anodizing treatment

Anodizing treatment is a commonly used surface treatment technique for aluminum veneer, which mainly involves forming an oxide film on the surface of the aluminum veneer to increase its corrosion resistance and wear resistance. This processing technique can form oxide films of different colors, such as silver white, gray, black, etc., which can be selected according to needs. Anodizing treatment can also increase the glossiness and texture of the surface of aluminum veneer, making it more beautiful.

1. Electrophoretic coating treatment

Electrophoretic coating treatment is an efficient surface treatment technology for aluminum veneer. Its main principle is to use the principle of electrophoresis to evenly spray the coating on the surface of aluminum veneer, in order to achieve the purpose of anti-corrosion, anti fouling, and waterproofing. This processing technique can form a uniform, smooth, and brightly colored coating with excellent decorative effects. Electrophoretic coating treatment can also improve the corrosion resistance and wear resistance of aluminum veneer surface, extending its service life.

1. Fluorocarbon spraying treatment

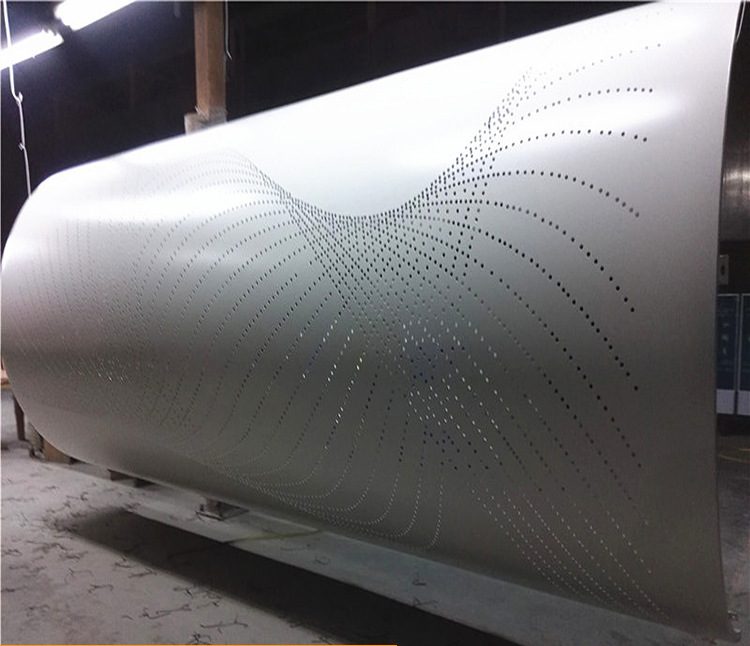

Fluorocarbon spraying treatment is a high-end surface treatment technology for aluminum veneer. Its main principle is to spray fluorocarbon coating on the surface of aluminum veneer to form a layer of coating with strong weather resistance and corrosion resistance. This coating has good hardness, glossiness, and durability, and can resist the erosion of natural environments such as ultraviolet rays, acid rain, and sandstorms. Fluorocarbon spraying treatment can also be designed with various colors and patterns as needed to meet different decorative needs.

1. Powder spraying treatment

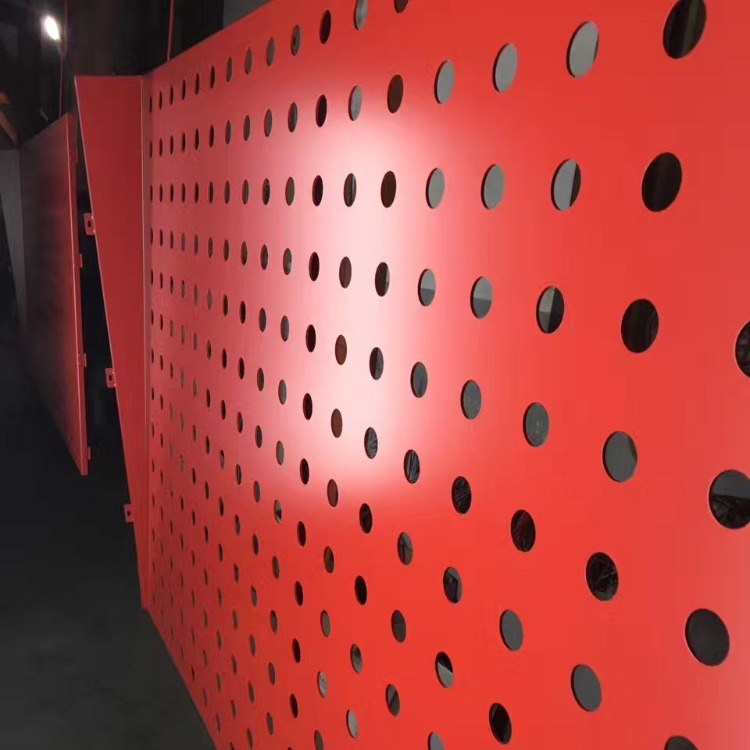

Powder spraying treatment is an environmentally friendly surface treatment technology for aluminum veneer. Its main principle is to evenly spray powder coating on the surface of aluminum veneer through a spray gun or roller to form a uniform and delicate coating. This coating has good decorative effect and durability, and does not contain harmful substances, which meets the requirements of modern environmental protection concepts. Powder coating treatment can also be designed with various colors and patterns as needed to meet different decorative needs.

The surface treatment technology of aluminum veneer is very diverse, and each technology has its unique characteristics and advantages. These characteristics make aluminum veneer a very suitable decorative material for modern architecture, creating a more beautiful and comfortable living environment for people.

Customer service QQ

Customer service QQ